Archive for March, 2014

Troubleshooting Damaged Chips

There’s a big difference between building one of something, and building a hundred. When building one, the challenge is simply to get the thing working at all. When building a hundred, the focus changes to issues like how fast you can do the build, and how reliably. Little problems that only crop up rarely start to become headaches. And if you’re like me, you start to get obsessed with achieving 100% reliability without sacrificing build speed or cost.

With Floppy Emu now past the 100 units mark, I can start to get some meaningful data from the assembly process. Thus far slightly more than 90% of the units I’ve built passed all my tests, and were able to be sold. Even for a hand-built piece of hardware, that’s not great. Getting closer to 100% yield will require troubleshooting what went wrong, and making sure it doesn’t happen again, but that’s easier said than done.

Releasing the Magic Smoke

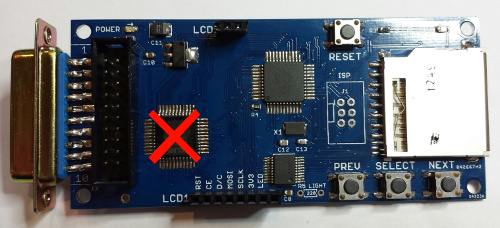

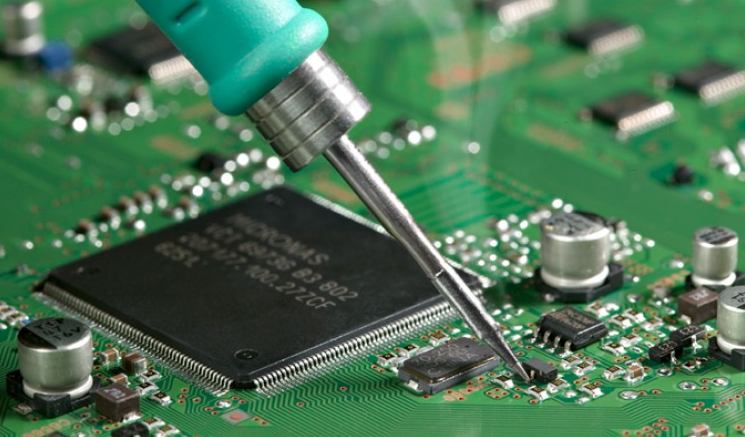

The most common failure I’ve seen is something I call “burnout”, and has affected about 4% of the units. After anywhere from one minute to a few hours of working normally, the Floppy Emu stops functioning, and both the 3.3V regulator and the CPLD become hot to the touch. The AVR, SD card, and LCD still seem to operate normally, but floppy emulation or anything else involving the CPLD no longer work. After some experimentation, I discovered that if the CPLD is removed and replaced using a hot air gun, the Floppy Emu can be returned to normal functioning and the problem does not reappear.

Hot chips imply a short circuit somewhere. Measuring the current draw is tricky, because Floppy Emu is normally connected directly to the Macintosh which powers it, and there’s no place to insert an ammeter inline and measure the current. I finally broke down and built a simple bench test rig, where the Floppy Emu is powered from an external power supply and no Macintosh is involved. This only provides a way to measure the current draw of the whole board, and not individual chips, but it’s better than nothing.

What I found is that a normal board idling on the main menu screen draws about 124 mA. Removing the CPLD with the hot air gun lowers this to 41 mA, implying that the CPLD and the incremental 3.3V regulator current are about 83 mA combined. That’s a bit more than the CPLD datasheet says is typical, but the actual supply current depends on how the CPLD is configured, so it’s within the realm of possibility. The CPLD current likely increases when the device is active and floppy emulation is happening, but I don’t have any way to measure that with the existing bench test rig.

Next, I measured a Floppy Emu in “half burnout” condition. This one actually functioned OK, but after several minutes it would grow pretty hot and stop working. Unlike the other burnout Emus I’ve had, this one would start working again if it were left to cool off for a minute. With my test rig, I measured this board’s idle current draw at 400 mA, more than three times higher than the normal board. Removing the CPLD dropped the current down to 41 mA again, so it seemed clear the trouble was related to the CPLD and not somewhere else.

So what’s going on with this burnout? It looks like something’s causing the CPLD to draw high amounts of current from the 3.3V regulator, resulting in high power dissipation and overheating in both chips. The regulator has an internal safety switch that will protect it from damage, but the CPLD apparently gets toasted. That makes sense, but what causes the high current draw in the first place? Like a good mystery detective, I came up with a few theories, which I think cover all the possibilities:

- The chip was defective. That’s possible, but blaming faulty chips should always be a last resort. In all the electronics projects I’ve ever built, only once have I ever encountered a problem that was conclusively linked to a faulty part.

- The PCB was faulty, and two closely-spaced CPLD traces were shorted together somewhere. The fact that replacing the CPLD fixed the problem seems to rule out this theory.

- A software error in the AVR program or the CPLD config caused two chips to simultaneously drive the same signal to different values. This seems unlikely, as almost all of the signals are unidirectional, and the only bidirectional signals are controlled by a simple mechanism that would be hard to go wrong. A software error should also affect all the hardware, not just a few units, unless it’s some rare timing-based error that only appears in very specific circumstances.

- The chip was damaged during assembly, due to static electricity or high heat. Possible, but I’ve never encountered a damaged AVR, and it’s the exact same package and pin count as the CPLD, and I handle it exactly the same way during assembly. Maybe the CPLD is more sensitive to mishandling somehow? Seems doubtful.

- I accidentally shorted two CPLD pins together with a poor soldering job. I carefully checked all the pins with a 10x magnifier, and couldn’t find any shorts. Still, this seems like the most plausible explanation.

- The “5V tolerant” chip isn’t very tolerant, and continuous 5V inputs eventually lead to damage. The datasheet seems clear this shouldn’t be true. Recommended operating conditions for a high input voltage are between 2.0 and 5.5 volts.

- “Bad” voltages from the Macintosh damage the CPLD, because it’s the only chip that’s directly connected to the Mac. I can’t rule this out, but it seems unlikely. It’s definitely possible for a vintage Mac’s 5V supply to be out of adjustment, but the CPLD is a 3.3V chip and doesn’t use the 5V directly. The Macintosh signal voltages could be out of whack, but I think that would also cause problems for the Mac itself.

- The Floppy Emu circuit design pushes the CPLD beyond its maximum ratings, causing damage. Maybe there’s some significant voltage overshoot or undershoot somewhere that can cause damage, or a big transient that happens at power-on. Possible, but without a specific culprit to investigate it’s hard to say.

Of these, the most likely explanations are the poor soldering job and the chip damage caused by a design that exceeds maximum ratings. Replacing the CPLD with a new one would fix both problems, since it replaces both the soldering job and the chip itself at the same time. To separate these theories, I took the “half burnout” board, removed the CPLD with the hot air gun, then resoldered the same CPLD. It still failed the same way, and drew exactly the same amount of current, demonstrating that the problem lay with the chip itself and not the soldering.

So I’ve got a few damaged CPLDs. Maybe they came defective from the factory (theory 1), maybe I damaged them during assembly (theory 4), or maybe a rare software bug causes damage (theory 3). Maybe an evil Mac is frying them with 12V logic signals (theory 7). But I’m betting on theory 8, and it’s somehow my own fault for a design that zaps the CPLD with occasional voltage overshoots, power-up transients, or other circuit gremlins that lead to failures in a small fraction of the CPLD chips.

Unfortunately there’s not a lot I can do to test this theory with the current hardware. I can only measure the current drawn by the whole board, not a single chip, and I can’t do any measurements while the board is connected to a Mac. Even if I could, an instantaneous surge in current would be met by the CPLD’s decoupling caps more than the power supply, so it might not even show up in any measurements I did. As for checking individual signals for overshoots or weird transients, it’s just not practical. The CPLD is a surface mount chip with tiny 0.5 mm pin spacing, so there’s no way to connect an oscilloscope or other probe. For now, then, there’s probably nothing to do but keep testing, and try to look for patterns in the timing and nature of future failures that might point to a more specific cause.

Read 41 comments and join the conversation

How to Manufacture a Widget

So you’ve designed an electronic gizmo, it works nicely, and the public wants to buy it. You’ve built one, or ten, or a hundred by hand until your soldering iron wore out, and now you’re ready to have the gizmo manufactured in a low-volume production run. Where do you go, and how do you get started? This is where I stand today with my Floppy Emu project, and I’ve spent the past few weeks researching the answers.

Step one is identifying and contacting potential manufacturers. This is harder than it looks! Electronics manufacturers generally don’t deal with “the public”, and you can’t just browse listings on amazon.com. Many of them seem to be semi-anonymous, with generic-sounding names like Electronic Systems, Inc. From my experience, the best way to find manufacturing candidates is to ask everyone you know for referrals. Dropping the name of a current client may also help make a manufacturer more willing to work with you.

If you’re an inexperienced one-person team looking for a production run of 50 or 100 units, be aware that most manufacturers won’t talk to you. They won’t even bother to reply when you contact them – you’re just not worth their time. Don’t be offended, just move on.

Somebody Set Up Us the BOM

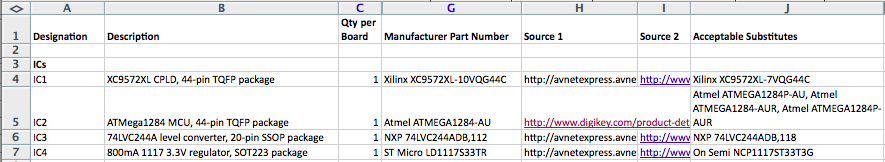

You can increase your chances of a favorable reply by being informed and organized when talking with the manufacturer. Have your Eagle/KiCad files and Gerbers ready to provide if requested. Make sure every part in your design is clearly identified with a designator like UC2 or R2, both in the design files and printed on the board itself. And most importantly, provide a detailed bill of materials (BOM) that defines exactly what part goes at UC3, R2, and everywhere else. If there are some footprints on the board that should be left empty, list those too. The more detail, the better.

Poor BOM:

- UC3 – ATMEGA1284P

- R2 – 220 Ohm resistor

- SW1 – push-button switch

Better BOM:

- UC3 – Atmel ATMEGA1284-AU, 44 pin TQFP package, http://www.digikey.com/product-detail/en/ATMEGA1284-AU/ATMEGA1284-AU-ND/2271240

- R2 – Yageo RC0805JR-07220RL 220 Ohm SMT resistor, 0805 package, 1/8 Watt, 20% tolerance, http://www.digikey.com/product-detail/en/RC0805JR-07220RL/311-220ARCT-ND/731230

- SW1 – TE FSM4JSMA 6x6mm 160gf SMD N.O. tactile switch, http://www.digikey.com/product-detail/en/FSM4JSMA/450-1129-ND/525821

- J2 – do not populate, leave empty

This saves the manufacturer a lot of time, eliminates potential confusion, and makes you look like you know what you’re doing.

Choosing a Manufacturer

After you get some manufacturers to reply with a quote, you just choose the cheapest one, right? Unfortunately it’s not that simple, even if cheapest were the only criteria. It’s often difficult to make an apples-to-apples comparison, because not all manufacturers provide the same services, and they don’t always structure quotes in the same way.

Some assemblers are assembly only, and it’s up to you to provide them with the blank PCBs and the parts. Others can handle that for you, either internally or externally. Most assemblers can also program any programmable chips on the board, and perform post-assembly custom testing if you desire. If you specify no custom testing, the default testing varies between assemblers, so be sure to ask. Does it include an electrical test for shorts or open circuits? Is there a visual inspection, and if so what do they check for? For my project I focused on manufacturers providing the full service of PCB manufacture, parts procurement, and assembly. Then I looked at options with and without programming and custom testing.

Order quantities matter a lot, and some manufacturers are optimized for different quantities than others. Your cheapest option for 50 units may not be your cheapest option for 200 units, or 1000.

Many manufacturers are in China, but be sure to investigate local options too. The labor cost will generally be cheaper in China, but the parts will cost about the same, while the lead times will be longer and the shipping costs higher. Especially if this is your first time manufacturing an electronics assembly, it may be worth paying a little extra to use a local manufacturer who can help walk you through the process.

From my experience, price quotes came in one of two general types: a generic NRE fee (non-recoverable engineering) plus rolled-up price per unit, or a more detailed cost breakdown with separate prices for PCB, parts, stencil, labor, etc. Make sure you know roughly how much your BOM parts should cost, so you can estimate the fraction of a rolled-up price per unit that’s assembly vs parts. A couple of examples may help (numbers are fictional):

Example Rolled-Up Price Quote:

NRE for manufacturing setup: $500, in addition to the quotes below Qty 50, 4 week turn: $48.00 each Qty 100, 4 week turn: $43.00 each

Quote includes:

- Fabrication of bare PCB with specs: 0.062" thickness

HASL finish (not lead-free) green soldermask 1 oz copper electrical test

- All parts and components per BOM - Soldering and assembly - Visual inspection for defects - Packaged in individual anti-static bags

Quote does not include:

- Power up or test of final assembly - Shipping cost to customer

Example Broken-Down Price Quote:

50 X PCB Manufacturing: 118.20 USD - Quantity: 50 - Max X-Dimension (cm): 10 - Max Y-Dimension (cm): 4.5 - Layers: 2 - PCB Thickness (mm): 1.6 - Copper Thickness: 1 oz - Surface Finish: HASL (Hot Air Solder Leveling) - E-Test Pass: 100% - Separated Sub-Boards: no

1 X Stencil Manufacturing: 49.00 USD

50 X BOM Part Sourcing: 1435.23 USD

50 X PCB Assembling, Manual + Stencil, 30 THT pins, 181 SMT pads: 755.49 USD

Depending on the complexity of your board, type of parts used, order quantity, and the manufacturer, I found that assembly costs for small volumes were typically in the range of $5 to $20 per board. If you’re finding prices substantially higher than that, keep looking. And if you’re finding prices substantially lower, let me know where!

Manufacturer Options

I talked with five different manufacturers. This was my experience:

SDM Assembly (Florida) – They were referred to me by someone on a vintage computing forum who had used them in the past. There’s no company website. I emailed the owner some details and questions, but didn’t hear anything back until six days later. He was friendly and polite, but said they were “assembly only” although they would be happy to do the assembly work if I sent them the PCBs and parts. I got the feeling they were a little overwhelmed with too much work. I never got a price quote.

Kalow Technologies (Vermont) – They contacted me, and I think somebody from Kalow reads the BMOW blog. They were friendly and helpful, but after looking at my design in detail they concluded they couldn’t do it economically, and declined to give me a price quote. I think they’re geared towards more full-service work including testing and packaging. They referred me to:

Imperial Electronic Assembly (Connecticut) – They were referred by Kalow. I contacted them, but never received a response.

Smart-Prototyping (China) – They made some of my PCBs, though I have no prior experience with their assembly work. The best part about Smart-Prototyping is that their formulas used to calculate assembly costs are right there on the web site, so you can do the math yourself. The price quotes for assembly without testing were fairly inexpensive. Testing is charged at a $28/hour labor rate. That seemed high to me – I thought a major reason for manufacturing in China was cheaper labor costs, but maybe that is cheaper. I don’t have anything to compare it to. Their price quote included a detailed break-down of all the costs, which I liked. Communication and questions (in English) went fairly smoothly, but the time difference meant every question and answer involved a 24 hour delay.

Microsystems Development Technologies (California) – They were referred by someone I once sold a computer too, who used them for his own retro-computing project. The owner responded quickly, and got me a price quote on a Saturday. Their quote was the rolled-up type, and for quantity 50 the assembly cost was about 75% more expensive than Smart Prototyping. For quantity 100, however, the price was about equal to Smart Prototyping. We exchanged many emails to answer questions and revise small details, and they always responded quickly and clearly.

In the end, I decided to go with Microsystems, even though they weren’t the cheapest option. The cost of assembly is only one part of the total manufacturing cost, which is dominated by the cost of parts. Even with the higher assembly cost, the total cost at Microsystems wasn’t too much higher than Smart-Prototyping. Spending the extra money to have a local manufacturing partner who’s good at answering questions and is close enough to visit in person feels like a smart investment. And I can always switch to a different manufacturer for future orders if I need to, but so far I’m happy with my choice.

Programming and Testing

Is it worthwhile having the manufacturer test your boards after assembling them? The assembler is responsible for delivering finished hardware that passes all the tests you specify, but if you don’t specify any tests, it’s uncertain what you might get. From talking to manufacturers, even with no testing they will still guarantee against egregious assembly errors like missing parts or parts installed backwards. They may also do basic electrical testing, like checking for power-to-ground shorts with a continuity meter.

Without further testing, there’s a risk that some boards will be defective and you’ll end up paying for non-working hardware. Typically this is caused by solder bridges between adjacent pins on a chip, or dry joints where the solder never bonded properly. Less often, problems will pop up due to damaged or defective parts. Without any post-assembly testing, Microsystems Development Technologies estimated 3-5% of boards might have such problems, but Smart-Protoyping estimated 10-20%. I suspect the difference is due to how pessimistic they are, rather than any inherent difference in their assembly processes.

If you’re making a small run of a few hundred units or less, the testing decision depends on cost and the predicted defect rate. If the expected defect rate is low, and you’re OK shipping potentially defective units to customers, then it might be OK to forgo testing entirely. If 3% of units are eventually returned as defective, but testing would have added 10% to the assembly cost, then you still come out ahead (although your reputation may suffer a bit).

If shipping potentially defective units is not OK, then somebody obviously must test them. Doing it yourself seems like a good way to save money, but don’t forget that your time has value too. If you can do the testing yourself in five minutes, or the manufacturer can do it for $1, it becomes a basic calculation of how much your time is worth to you. Don’t forget that money paid to the manufacturer for testing is tax-deductible, but the value of your own time spent testing is not, unless you incorporate your business and pay yourself a salary.

I think many people in this situation shy away from having the manufacturer do testing because they don’t know how to define the testing requirements, rather than because of the testing cost. That’s certainly true in my case. Is the manufacturer going to hook up a Mac Plus and run some test programs on the Floppy Emu hardware? It seems hard to imagine. Even quantifying exactly what to test, and how to test it, and what results to expect can feel so onerous that it may seem easier just to skip it completely.

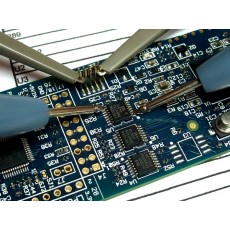

Most manufacturers can also do firmware flashing for any programmable parts on your board. This can be done via your programming header after assembly is complete, or in some cases the bare chip can be programmed before assembly (I wish I knew how that worked). This might seem like a waste of money when you can very well program the firmware yourself, but again it’s a question of the value of your time. Do you want to spend two hours plugging and unplugging cables to program the firmware for 100 boards? Or do you want to pay someone else $50 to do it? Flashing the firmware can also serve as a cheap and easy method of testing, since some defective boards will fail the firmware update and be sent for a re-check without needing further tests.

Floppy Emu Self-Test

After way too many hours of deliberation, I decided that Floppy Emu’s manufacturer will do firmware programming and testing. This will add about 5% to the cost, and still won’t catch 100% of assembly problems, but I think it’s money well-spent. When considering the firmware programming by itself, I was ambivalent about having them do it or doing it myself. But the big advantage of having the manufacturer do the firmware programming is that I can include a self-test program in the firmware, which checks the majority of the board’s functions in just a few seconds. So I’m paying them a fair price to do firmware programming I’d otherwise have to do myself, and then I get the benefit of some extra testing almost for free.

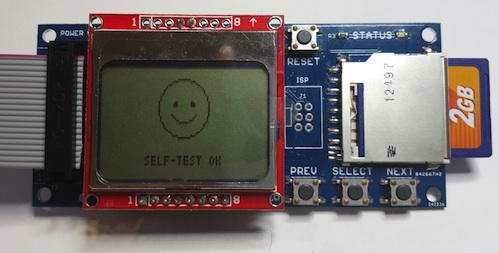

What is this self-test, you ask? I’ve been busy putting it together over the past few days, and I’m pretty excited about it. Previously there weren’t any self-test or diagnostic routines of any kind – Floppy Emu just powered on and started working (or not), and that was it. But now it takes a few milliseconds to:

- verify the AVR fuse settings

- verify the version number reported by the CPLD matches what’s expected

- exercise all the lines that connect between the AVR and CPLD to check for bridges, shorts, or open circuits

- verify that the SD card initialized correctly

The “exercise all the lines” test required some substantial re-plumbing of the CPLD, and significant changes on the AVR side too, so thorough testing is needed to be sure I didn’t break anything. But once it’s working, it should be a major time-saver.

The self-test routine concludes with a happy face if everything is OK, a sad face plus error message if a test fails, and a question mark if something is missing (no SD card, or CPLD is blank). I can’t assume that whoever’s running the test is fluent in English, so icons seemed like the way to go.

The manufacturer’s full firmware programming and testing procedure will be:

- flash the AVR microcontroller

- insert SD card

- update the CPLD firmware from the SD card

- press RESET button and check for the happy face on the LCD display

I’ve timed this repeatedly, and it takes about 1 minute 20 seconds, including the time needed to plug and unplug all the cables, cards, and the LCD. Directly or indirectly, this procedure will test everything except the CPLD-to-Macintosh interface (10 pins), the SELECT button, and the SD card write-protect signal. It’s not a perfect test because the CPLD-to-Mac pins aren’t covered, and occasionally my Mac-based testing uncovers intermittent I/O errors that wouldn’t be detected by this kind of testing anyway. But it should catch the majority of typical assembly errors, while also saving me the time needed for firmware programming, all at a reasonable cost. Check back in about four weeks to see how it turned out!

Read 8 comments and join the conversation

Taking Care of Business

Today was time for some especially gruesome business-related work. I knew I was overdue for collecting California state sales taxes on Floppy Emu sales, and my recent investigations into having an electronics assembler build the boards brought some new urgency to this issue. Without a California seller’s permit and resale certificate, I would have to pay sales tax on the entire order from the assembler, because they’re also in California. In fact, I’ve already been paying sales tax on all the parts I’ve purchased from Digi-Key and other electronic component vendors. That stinks, because in theory I shouldn’t need to pay sales tax on parts I purchase that are later resold to other people. But avoiding the tax requires having the proper paperwork, and also means collecting sales tax from California residents who buy a Floppy Emu.

After a highly-extensive (ahem) 90 minute Google search, I found that setting up all this sales tax craziness wasn’t nearly as difficult as I’d feared. My new best friends at the California State Board of Equalization were there to help (and to make us all equal, apparently). I was able to apply for a seller’s permit online, and was approved immediately. From there, I can fill out resale certificates with my permit number, and give them to the suppliers from whom I purchase parts. Voila, no more sales tax!

Of course it’s not all flowers and smiley faces… I’m now responsible for regular filing of a California sales and use tax return, form BOE-401. But because I’m a small business with low revenues, I can file the “EZ” version of this return, which is only one page long. Essentially all I need to do is state my gross revenues, and the amount of revenues exempt from sales tax because the buyer is outside California, then multiply the taxable remainder by the state sales tax rate to determine how much I owe the state. What could go wrong? Probably a lot of things, but at least it looks simple on the surface.

The other half of this deal is that I now need to collect sales tax on purchases from California residents. I’ve had surprisingly few of those – Australia has bought far more Floppy Emus than California, for example – but it’s a requirement with the potential to introduce new headaches. Fortunately in this case, PayPal makes it very easy to collect sales tax from the right people. It took less than 60 seconds to reconfigure my ordering page to charge sales tax for buyers with a California shipping address.

You might be wondering how much the California sales tax rate is, and that’s a good question. As it turns out, it’s different depending on where you are in the state! The state itself collects 7.5%, but most counties and cities add a few percent more on top of that. Technically I think I’m supposed to charge a different sales tax rate to different California buyers depending on which county they’re in, but forget it. Where I live, it’s 9%. Hey, this is Silicon Valley, and we like our highways gold-plated and our fire trucks rolling with diamond bling! Or maybe it all just goes to subsidize jet fuel for Google execs, I don’t know.

Read 8 comments and join the conversation

Outsourced PCB Assembly and Testing

Help request! If any reader has experience taking a hobby-scale electronics project to an outside vendor for assembly, I’d love to hear from you. I’ve been talking with the fab in China that makes the Floppy Emu PCBs, and they can do the full assembly process for a reasonable price. That means making the PCBs, ordering all the components, and doing 95% of the assembly. I’ll add the DB-19 connector and LCD myself. But I’m stuck on determining what kind of testing to request from them, if any. It seems like a simple question, but I don’t have the experience to know what kind of failures to test for or what failure rate is typical.

The vendor will send me hardware that passes whatever tests I specify. If a board fails a test, it’s up to them to find out the problem and fix it. Ideally they’d do a full functional test – the same test I do before shipping a Floppy Emu – but that’s not practical for several reasons. I’d have to ship several vintage Macs to Shenzhen, and give them instructions on how to use old System 2.0 software and perform a non-automated series of file copy tests. Assuming they were even willing to do this, it would be expensive and time-consuming, and I’m not sure I’d even trust them to do it correctly.

At the other end of the spectrum, they could do a basic power-on test. Apply power, and confirm that the power LED turns on. But that wouldn’t really prove much except that there are no power-to-ground shorts. There could be all kinds of horrible problems with the board, but the LED would still turn on and the test would still pass. Furthermore, it’s not so easy to “power on” a Floppy Emu without having a Mac, since it’s meant to be powered through the floppy port. I’d have to build them some kind of power adapter, or they’d need to connect test leads to specific pins on the board to power it.

A mid-level test would be for them to flash the AVR firmware, then confirm that the status LED blinks three times at power-on (the normal behavior). That would at least show that the AVR was working correctly. But it wouldn’t do anything to test the SD card interface, or the CPLD, or the LCD interface. And there would still be the same challenge of powering the hardware without having a Mac to connect with it.

What makes this difficult is not knowing what kind of failure rate is typical, nor what kind of failures. If I specified no tests at all, and they installed an IC backwards in all the boards, I could get a 100% failure rate. Would something like that be my responsibility, or theirs? If I didn’t provide any tests at all, they could theoretically send me anything and have still met their obligation.

Lastly, the cost of testing time is somewhat expensive relative to the cost of the hardware. For a run of 50 units, for each 1 minute per unit spent on testing, it’s the same cost as if they did no testing and 1 unit was defective and discarded. For example if they spent 5 minutes per unit on testing, I could afford to have 5 of the 50 units be defective and unusable – a 10% failure rate – for the same cost. Since 5 minutes of testing still wouldn’t guarantee a 0% failure rate anyway, the cost of testing begins to look questionable unless the typical failure rate is high.

Working out testing details with someone who’s on the other side of the planet and who’s not a native English speaker can be difficult. I tried to find an electronics assembler in the United States, but had terrible results. One place actually contacted me, after reading the blog, but they later said they couldn’t handle my order and referred me to a second US vendor. I contacted the second vendor, but they never responded. A third US vendor was referred to me by a friend of a friend. I sent them a detailed description of the project and some questions about their process, but heard nothing for more than a week. Finally they wrote back with a generic reply, without quoting any price or answering any of the questions I’d asked. A fourth US vendor was referred to me by another retro-computer enthusiast I know, but so far I’ve had no response from that vendor either. In contrast, the Chinese shop sent me a detailed quote within 24 hours of my first inquiry, and was happy to have my business.

In a perfect world I’d have a test that was easy to run, quick, required no extra equipment, and could catch near 100% of the possible problems. But I don’t have that, or even anything close. So I’m leaning towards no testing, but my nightmare scenario is to spend lots of money and receive 50 units that are all broken, due to some kind of systematic assembly problem.

Has anyone else been through this process before? What was your experience?

Read 8 comments and join the conversationMoar Floppy Emu!

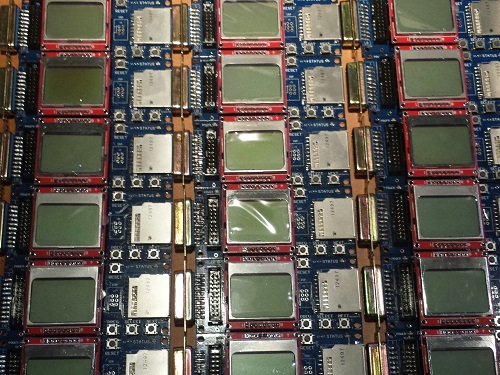

With the missing parts finally on hand, I was able put in some quality soldering time this weekend and build a whole pile of Floppy Emus. If you’ve been waiting, then wait no longer: they’re available now on the Floppy Emu page. It was a soldering ultra-marathon, and wow, was it tedious! I’ll definitely be looking into options for having an electronics shop assemble boards in larger batches in the future. I wish there were an easy way to hand-off the programming, testing, and order fulfillment too, as those tasks are surprisingly time-consuming. Many assembly shops can do programming and testing too, but when your test routine begins with “turn on the Macintosh Plus”, the conversation doesn’t go very well.

Most of the new batch of Floppy Emus were sold within 12 hours of putting them out for sale, before I’d even had a chance to mention it here on the blog, so hopefully there will still be some left by the time you read this. In fact, the level of interest remains surprisingly high for such a niche product, and to be honest I’m a little bewildered by it. Sure it’s a neat little gizmo, but I never would have guessed there were so many people out there with Mac SE/30’s rattling around in their closets, looking for a floppy emulation solution. Who are you people? Don’t you have anything better to do? You’re crazy! But I love you anyway.

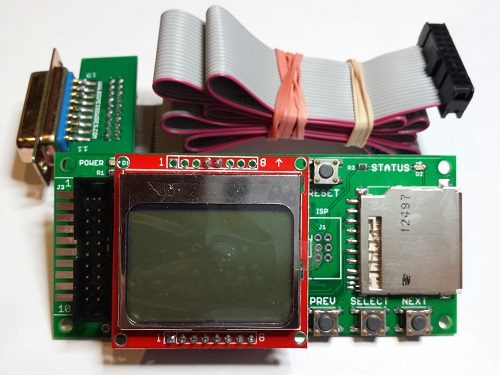

With this batch of hardware, I’m also introducing a new variant of the Floppy Emu. For an extra $13, you can get the DB-19 floppy connector on a 36 inch extension cable, instead of having it built-in directly to the Floppy Emu board. This provides some extra flexibility for positioning the Floppy Emu where it’s convenient for you to see it and press the menu buttons. It’s similar to what you’d get with IEC’s cable, only now you can get it at the same time that you purchase the emulator.

The extension cable uses a tiny circuit board to adapt the DB-19 floppy connector to a standard IDC-20 header, then adds an IDC-20 to IDC-20 cable. Using a custom circuit board here seems a little like overkill, but I was unable to find a DB-19 shrouded header anywhere. The whole cable assembly is hand-built by me. This new extension cable Floppy Emu variant is an experiment, and I’ll be looking to see how popular it becomes, and how tedious it is to make the cables. If the experiment doesn’t go well, I’ll probably return to selling only the original variant with the built-in DB-19 floppy connector, and let IEC have the extension cable business for those who want one.

Read 5 comments and join the conversation