Discovery Day!

Every year I lead a group of kids in the construction of an “Electric Scribbling Machine”, as part of the local elementary school’s Discovery Day program. The program sessions are run by parents and local community members, and can be anything from karate to marshmallow cannons to frog dissection. The kids range in age from 7 to 10 years, and the sessions are only 50 minutes long, so it’s a challenge to design interesting projects to fit the available time and skill level of the kids. Despite the challenges, we always manage to have lots of fun!

The scribbling machine concept is simple:

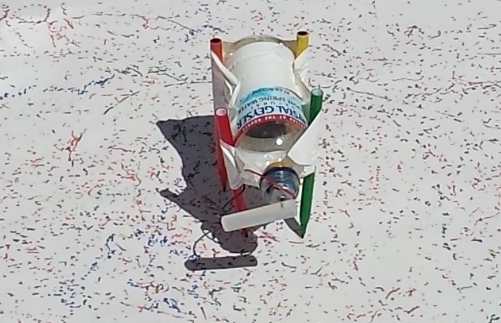

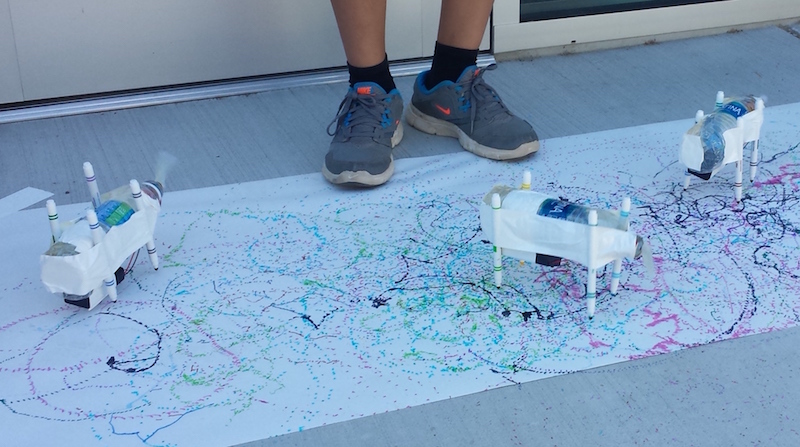

- Attach an off-center weight to an electric motor, so it wobbles and vibrates

- Attach the motor to some kind of body

- Attach colored markers to the body as “legs”

- Set the machine on a large sheet of paper, and watch it go!

I use cheap DC hobby motors rated for 1.5V to 6.0V, with an AA battery. The off-center weight is a glue stick (designed for a hot glue gun), with a small pre-cut hole that press-fits onto the motor shaft. The body is an empty plastic water bottle, and the legs are washable Crayola markers. What could go wrong?

If you guessed there would be tons of problems, you’re right. In past years, we used rubber bands to hold the battery and legs to the body, and the motor wires to the battery. Kids and rubber bands don’t mix well in this project – most of them lack the physical dexterity needed to twist a rubber band around two objects and hold them in place. They struggle with it, accidentally crush the water bottle, and get frustrated. Rubber bands on the battery for the motor wires are also a problem. You can imagine how unreliable that connection can be, and there’s no easy on/off switch.

A New Design for 2016

This year we made two big changes to the design. I bought a pile of 2xAA battery holders with an integrated on/off switch, for a much simpler and frustration-free electrical connection. And I replaced all the rubber bands with duct tape. Who doesn’t love duct tape? With these changes, we were guaranteed a problem-free Discovery Day, right?

The battery holders were a clear improvement, and I was pleased with how they worked out. The duct tape was a mixed bag. It was certainly easier for the kids, and it allowed the legs to be attached in more orientations than are possible with rubber bands. But if you’re not the parent of an 8-year-old, it may be hard to appreciate just how big of a mess kids can make with tape. There were wads of snarled tape everywhere, and when someone wanted to un-tape a leg and make an adjustment, it was difficult.

I could live with snarled tape, but the bigger issue came from an unexpected source: the solder connections. Of 24 battery and motor packs, we had at least 12 that failed in various ways. Sometimes the wire broke off at the motor, and sometimes at the battery pack. This was a surprise, since we used the same motors soldered in the same way as previous years, where I’d only ever experienced one or two breaks before. During the first session, we went through all of the packs for that session and half of the packs intended for the second session. I raced home to get my soldering iron during the short break between sessions, and repaired as many packs as I could. In the end we had enough for everyone, but the fragility of the packs was surprising and frustrating for the kids.

After the scribbling machines were more-or-less finished, it was great to see some of the kids experimenting with different designs. Longer or shorter legs, angled or straight, flat-footed or precariously balanced… each produced a different kind of motion in the resulting machine. Some spun in lazy circles, while others raced straight ahead like a car. All of them made interesting spiral and dot patterns on the paper as they went.

I believe I used the words “magnetic field” at least once during the session, so that counts as educational. Success!

6 Comments so far

Leave a reply. For customer support issues, please use the Customer Support link instead of writing comments.

Thanks for the update on this — I will definitely do this with my Cub Scouts next term.

You decided against the laser cut \’platform\’ concept?

Right. There were actually a few different laser cut concepts, only one of which was discussed here a few months ago. The one I finally built was quite different from that one – it had many different interlocking parts instead of a single plate, so it could form fixed-angle legs. And it wasn’t a vibration-based design, but instead had the shaft of the motor directly on the floor, spinning the whole machine very rapidly. It sort of worked, but it was too flimsy and fiddly to build, and was going to be too expensive. I got a bit discouraged after that, and returned to the tried-and-true water bottle design, with a few new mods as described in this posting.

I belatedly realized why so many wires broke this year. It wasn’t the solder connections, but the wire itself. In past years I supplied my own solid core wire for the battery-to-motor connections. But this year, I used the wires that came pre-attached to the battery holders, which were some narrow gauge stranded wire. I’m not sure how to avoid this next year – when purchasing a battery holder, the wire type and gauge typically isn’t mentioned in the advertisement.

How about a blob of hot glue melted all around the wire to motor connection point to stiffen things up?

That was a great write-up for this project! Have you thought about velcro instead of tape for attaching the markers to the body? If you wrapped the bottle in velcro, it would still allow for experimentation with leg placement. Though, there may be issues keeping the legs fixed in place.

Just saw this so I thought I’d put in my $.02. Instead of duct tape, take a look at what’s called “gaff tape”. It’s what duct tape wants to be when it grows up – strong, easily tearable, secure, and doesn’t leave tape residue. Expensive (typically a 60yd roll@2″ ~$15-20), but worth it. It’s the life-blood of the entertainment industry.