Archive for the 'Yellowstone' Category

The Amazing Disk II Controller Card

In the world of Apple II disks, there are two major types of disk controller cards: the original Disk II controller (and clones), and everything else. Both have their place. The “everything else” category includes the Apple 3.5 disk controller card, Liron card, SCSI cards, IDE cards, and more. These cards provide a standard API for software to read/write blocks, get drive status, and format the disk, all without requiring the software to know anything about how the disk actually works. These cards have built-in smarts to handle the low-level details. In contrast the original Disk II controller card is dumb as dirt, and forces the software to handle virtually all of the low-level details. And yet it’s an amazing piece of technology for its time.

The first Apple II models had no built-in floppy disk support. The Disk II controller was cleverly designed to add that missing support at a very low cost, and was a major reason why Apple II computers became so popular. This disk controller was simpler, and cheaper, and more flexible, and just all-around better than any of its contemporary competition. It’s the ultimate example of Woz can-do technology.

Floppy Disk 101

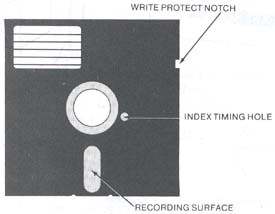

A floppy disk is just a plastic circle with a magnetic coating. Loaded into a drive, the disk rotates at about 300 RPM. A stepper motor moves the read/write head linearly from the center of the disk to the outer rim. This arrangement provides for a few dozen concentric rings where a serial stream of 1s and 0s can be stored.

How do you get from these basics to higher-level concepts like bytes, tracks, and sectors? How are logical data bytes encoded into bit patterns on the disk? When reading the disk, how are the bits framed into bytes? How do you find track zero, or the boundaries between sectors? The conventional answer to these questions in the 1970s was extra hardware, and lots of it. This made the disk controllers and the drives themselves complex and expensive, putting them mostly out-of-reach for an inexpensive home computer system.

It was late 1977 when Apple set its sights on finding an alternative to cassette tape data storage, and began looking into options for a floppy drive for the Apple II. They were still a small and unproven company, and the Apple II had only been available for about six months. Woz didn’t know much about the subject of floppy disks, but he agreed to take on the challenge.

Woz’s approach was to remove virtually all of the hardware that controls the disk, and take a software-driven approach akin to bit-banging. Apple went to Shugart, the inventors of the 5.25 inch floppy drive, and requested a stripped-down version of Shugart’s SA400 drive with most of the control electronics removed. It was just a simple mechanism with one motor for spinning the disk and a stepper motor for moving the read/write head. As the legend goes, the entire Disk II hardware design was conceived and built by Woz and Randy Wigginton over a few weeks during Christmas vacation 1977, including writing the first version of DOS, and the working disk drive was demoed at CES in January 1978. Additional help was provided by Apple engineers Cliff Huston and Wendell Sander. 40+ years later I’m amazed by how quickly this small team was able to make everything work.

A few years ago I asked Woz about the Disk II development, and he said this:

I have no idea how I came up with that incredible disk controller. I was good at creating anything in electronics, analog or digital. I had no prior experience of any kind, not even in classes, regarding disk hardware or software. So my thinking had to be from the ground up. I had to sense data coming from the disk and make decisions about 0’s and 1’s based on timing.

I had taken a graduate level course at Berkeley (although an undergrad, I only took grad courses in anything having to do with computers in any university) on state machines and thought of how I could use 2 simple low cost chips as a state machine to do this, sort of a minimal microprocessor hand-built. At the time I just knew that it would read and write data but I assumed that I was leaving out many ingredients of a disk controller due to not knowing what they did. I assumed this because my design took so few parts. But in the end, mine did more in some good ways, especially since it was in the computer and tied to software that could alter how it worked, which eventually led to greater storage and faster speed that would not have been possible using the normal disk. Plus, I took about 20 chips off the drive itself and bypassed them from my own controller, because they were just middlemen that got in the way of things.

The best work I did, over and over, was partly due to not having money and having to learn how to use the fewest parts of anyone, and also due to the fact that everything great I created I had never done before.

A Tour Of The Disk II Controller

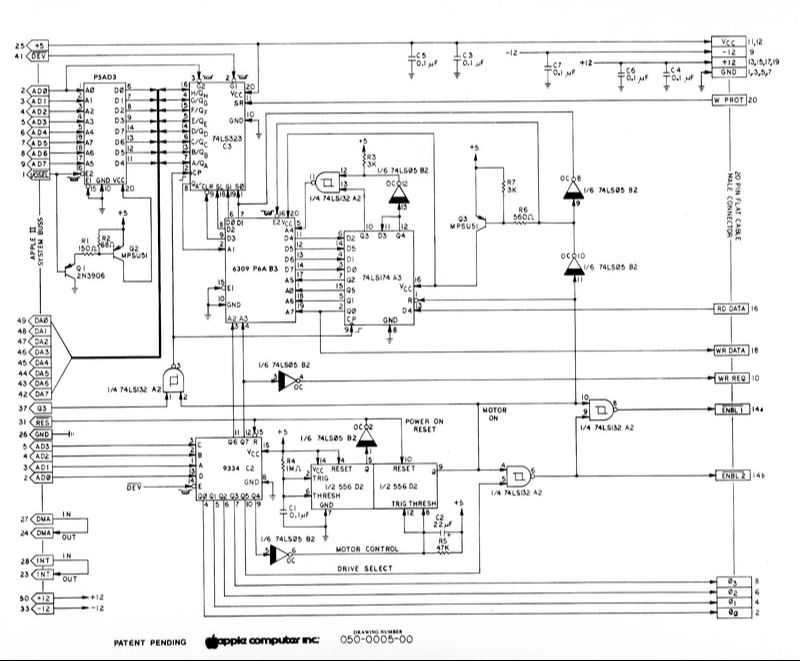

The Disk II controller card is basically just a fancy shift register. It knows how to read and write bits at a fixed rate of 1 bit every 4 microseconds. The card also has a tiny 256 byte ROM containing bootstrap code that runs when the computer first turns on. It’s a minimal 6502 program with just enough smarts to locate track 0, sector 0, load it into the computer’s memory, and then execute it. Every other aspect of disk control is handled by software.

The card contains only eight simple chips. There’s a 256 byte ROM containing the bootstrap code, and a second 256 byte ROM used as part of a state machine (more on this in a moment). There’s also a 74LS174 hex flip flop providing the inputs for the state machine. A 74LS323 eight bit shift register is the heart of the whole design. A 74LS259 addressable latch stores the desired state of the motors and the drive 1 or 2 selection. There’s a 556 dual timer, and a 74LS05 hex inverter and 74LS132 quad NAND to provide some needed glue logic. That’s it. That’s the entire disk controller. Here’s the schematic:

Let’s go through the challenges of floppy disk I/O one at a time, and look at how the Disk II controller design solved them.

Challenge #1: byte framing. The data coming from the disk is a continuous stream of 1s and 0s, and there are no start or stop bits. So how do you know where one byte ends and the next byte begins? Woz’s solution was to require that every byte written to the disk have 1 as the most significant bit. During a disk read, the state machine takes bits from the disk one at a time, moving the shift register one position left and appending the new bit at the right. It keeps going until the left-most bit position holds a 1, at which point the state machine says “Aha! Here is a complete byte!” Then the CPU stores the byte, and the process begins again. The state machine clears the shift register after the MSB becomes 1, so it’s ready to shift in the eight bits for the next byte.

By itself this solution isn’t enough. If the state machine starts reading bits in what was actually the middle of a byte, it will probably misinterpret a 1 bit in the middle of the byte as being the 1 bit for the MSB position. But this scheme ensures that if the state machine gets the byte framing correct just once, whether by luck or another method, it will continue to be correct from then on. So the challenge is finding a way to guarantee the framing is correct before beginning to read disk data.

The conventional solution is to write a special 50-bit pattern of so-called sync bytes to the disk, immediately before each sector. These aren’t really bytes at all, but a 10-bit pattern 1111111100 repeated five times. This pattern has the interesting property that no matter where the byte framing is initially, it will fall into correct synchronization after at most five repetitions of the pattern, just by following the state machine rules described previously. This solution is entirely software-driven, and is merely a convention. The hardware itself has no mechanism to guarantee correct byte framing. There are other methods of ensuring framing, and some of the bizarre richness of Apple II copy-protection schemes arises from different approaches to framing taken by the custom I/O routines in many games.

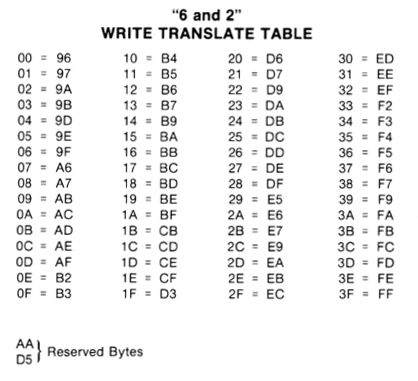

Challenge #2: byte encoding. If every byte written to disk must have 1 as the MSB, then how do you write a zero byte, or any other byte with a value less than 128? And there are other restrictions too: every byte written to disk must have no more than two consecutive zero bits. If there are three consecutive zero bits, the disk hardware can’t reliably read back the data. Given these two requirements, there are only 66 possible 8-bit values that are permitted to be written to the disk. How then can arbitrary 8-bit values be stored?

The answer is to split up the logical 8-bit bytes, and store their bits in subgroups as part of multiple disk bytes. The standard way of doing this is a GCR encoding scheme called 6-and-2. With 66 possible values for the disk byte, and two reserved values, that leaves 64 possible disk bytes for encoding data. 64 is 2 to the 6th power, so six logical bits can be encoded in every disk byte. A series of three disk bytes can encode the first six bits of three logical bytes, and a final fourth disk byte can encode the last two bits of the three logical bytes, concatenated together. This means the number of bytes stored on disk is 4/3 times the number of logical bytes, ignoring headers and checksums and padding.

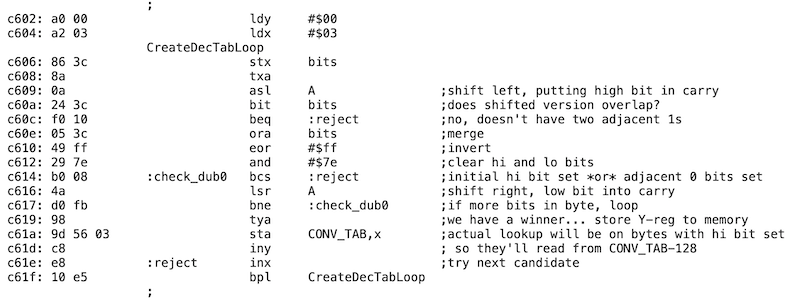

You might wonder how the Disk II controller bootstrap code accomplishes the GCR decoding for sector 0, track 0. At first glance, it would seem to require storing a 64-entry reverse lookup table in ROM, which is already one quarter of the very limited ROM space available. The bootstrap code actually uses a much cleverer solution, and constructs a 256-entry forward lookup table in RAM on the fly, using only 30 bytes of 6502 code!

The Apple II floppy byte encoding has evolved over time, resulting in a changing number of sectors and total disk capacity. The first version of the Disk II controller card didn’t permit any consecutive zeroes to be written to the disk. This further limited the number of possible disk bytes, and forced the use of a less efficient 5-and-3 encoding scheme. It was only possible to fit 13 sectors per track, resulting in 114 KB total disk capacity. Apple DOS 3.1 and 3.2 used the 5-and-3 scheme. Eventually Woz or one of his teammates realized that with a small change to the state machine, it would be possible to read two consecutive zeroes reliably. All it required was a change to the contents of the state machine ROM, essentially fixing a small bug in order to make the bit timing measurements more reliable. No hardware changes were needed to the Disk II controller. The more efficient 6-and-2 scheme was introduced beginning with DOS 3.3, ushering in the 16 sector tracks and 140K disks we’re familiar with now.

As with the byte framing, this whole encoding scheme is purely a software convention. There’s nothing about the hardware that implements 6-and-2 or 5-and-3 or any other encoding method. Sector 0 track 0 must be encoded using 6-and-2, because that’s what the ROM bootstrap code expects, but after that anything goes. Software is free to use any other encoding scheme it wishes, and many copy-protected programs use novel encoding schemes in order to obfuscate their workings.

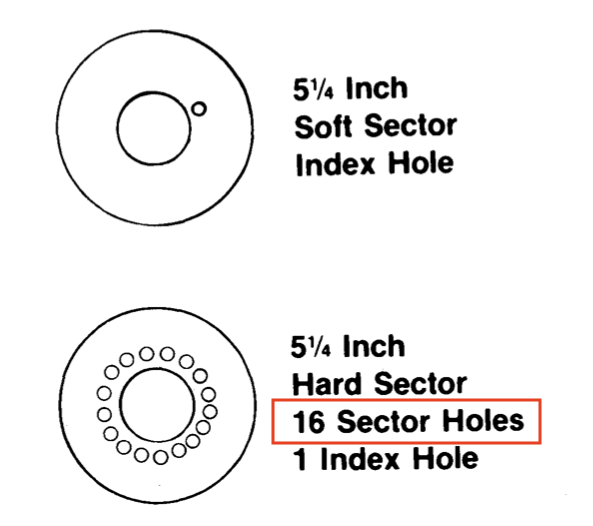

Challenge #3: sectoring. Once you’ve got the bitstream correctly framed into disk bytes, and the disk bytes correctly decoded into logical bytes, how do you make any sense of the data? It’s a ring buffer, so how do you know where the data begins and ends? 1970s floppy disks often used one or more small holes punched in the disk at regular intervals around the circumference. A small opening was cut in the disk’s dust jacket in order to reveal the index holes as they passed underneath. Hardware inside the disk drive sensed when these holes passed by as the disk rotated, and this information was used to determine where a new track or new sector began.

It’s easy to see why this might be undesirable. The hole-sensing hardware adds extra complexity and cost. And in the case of hard-sectored floppies with a hole for every sector, the number of sectors becomes part of the hardware design and can’t be changed. Apple’s move from 13-sector to 16-sector format would have been impossible with hard-sectored disks.

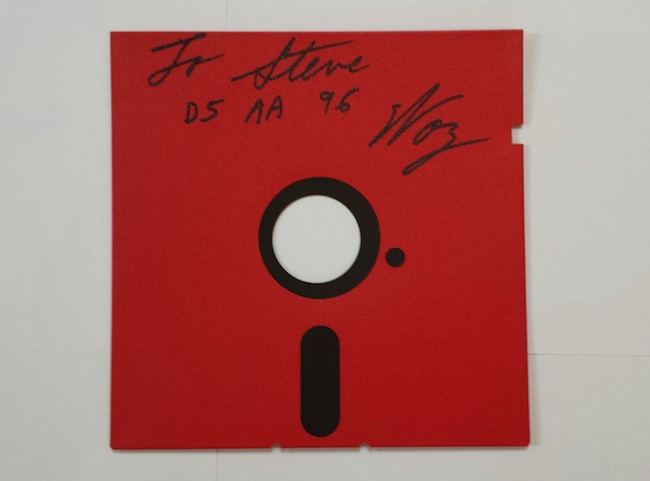

The Disk II design takes a software-driven approach to sectoring. Any index holes on the disk are ignored. When it wants to find a particular sector on the current track, the computer begins reading bytes, ignoring everything it sees until it finds the three-byte sequence D5 AA 96. This signature marks the beginning of a new sector on the disk, and is possibly the most famous byte sequence in the entire kingdom of Apple II arcana. On the wall of my office hangs a 5.25 inch floppy disk with a D5 AA 96 greeting signed by Woz himself:

A short sector header follows this signature, and among other things the header contains the sector number. If it’s the sector number the computer was looking for, then it reads the bytes that follow. If it’s not the right sector, then it keeps looking for another D5 AA 96 to indicate the beginning of the next sector, and tries again.

This whole business is – you guessed it – purely a software convention. The D5 AA 96 signature, the sector header, the length of sectors, and everything else are merely conventions. There’s nothing whatsoever about the Disk II controller card hardware that requires software to work this way, and some software takes a different approach. One well-known example was the game Prince of Persia, which used a custom scheme called RWTS18 that was optimized for reading as opposed to writing, and used six 768-byte sectors per track instead of the standard sixteen 256-byte sectors.

Challenge #4: finding tracks. So far we’ve only discussed data in a single one of the concentric rings on the disk. These rings are usually called tracks, but as we’ll see, the definition of exactly what constitutes a track can sometimes be fuzzy. So how do you switch between tracks, or locate a specific track? And just how many tracks are there? The Disk II and its controller hardware don’t answer these questions. Instead, it’s all (say it with me now) software-driven.

On the disk media there’s no such thing as a track – it’s just a featureless round expanse of magnetic media. Tracks are created when the read/write head remains at a fixed radial position while the disk spins underneath and bits are written. Then the head moves inward or outward to a new radial position, and writes a new track.

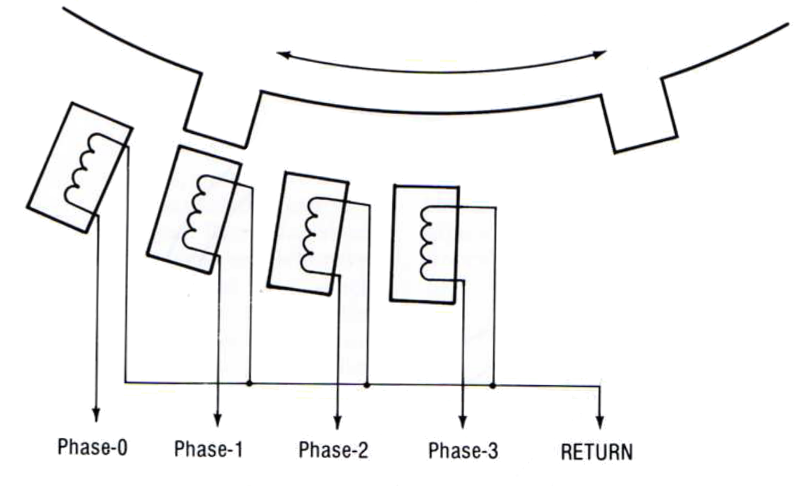

The head movement is controlled by a stepper motor, under direct software control. The stepper consists of four electromagnets, and at any moment the software can turn any of them on or off. A series of permanent magnets are attached to a gear that moves the read/write head, and by activating the electromagnets in the right sequence, they can attract or repel the permanent magnets and move the head. If stepper electromagnet 0 was on, and then electromagnet 1 is turned on and electromagnet 0 turned off, the head will move a small radial distance. Then if electromagnet 2 is turned on and electromagnet 1 turned off, the head will move further in the same direction.

How closely can you space the tracks? It turns out that two of these head movements are normally needed in order to move the head far enough so that a track won’t interfere with its neighbors. If you try to write tracks with only one head movement between them, the magnetized areas of the disk media from the adjacent tracks will bleed into each other and cause a mess. For this reason, two movements are normally considered to be equal to one track, and a single movement is a half track. Quarter tracks are also possible, but aren’t used by most software. If electromagnet 0 was on, and then electromagnet 1 is also turned on, the head will move a quarter track. If electromagnet 0 is then turned off, the head will move an additional quarter track.

The method of locating track 0 is as crude as can be. The disk controller doesn’t know at what track the read/write head is currently located, so software must activate the stepper motors in sequence in order to move the head continuously in the direction of track 0. Eventually the head will reach track 0 and can move no further, but the software will keep activating the stepper motors, driving the head against a mechanical stop and producing the familiar rat-a-tat sound of an Apple II floppy drive during boot-up. After 80 half steps, the head is guaranteed to be at track 0. From that point on the software must keep track of all stepping movements, and remember what track the head is currently on, in order to perform relative steps. If the software gets confused, say by reading what it thinks is track 20 but finding data for a different track there, it will usually recalibrate by repeating the track 0 seek and then immediately stepping back to the desired track. This creates a clack-clack sound that many long-time Apple II users will recognize as the sign of a failing disk.

It’s customary to store 35 tracks per disk, but this is merely a convention. The true limit varies slightly from one drive to the next, and is determined by the maximum and minimum linear positions of the read/write head. Non-standard disks with up to 40 tracks are sometimes seen.

Copy-protected Apple II games very often play funny tricks with track stepping. A simple trick is locating a track at some odd number of half-steps from track 0. Tracks must be at least two half steps apart, but there’s no rule saying they can’t be three half steps apart, so you might find a game disk with data on tracks 0, 1, 2.5 and 4. This will confuse disk copy programs that only expect to find data on integer numbered tracks.

A more advanced trick is writing data on two tracks that are just a half step apart, but only using half the circumference of the disk for each track, so the magnetized areas won’t interfere with each other. There might be a half-track’s worth of data at track 2 from twelve o’clock to six o’clock around the disk, and then another half-track’s worth of data at track 2.5 from six o’clock back around to twelve o’clock. Data that’s written this way is easy to read, but is difficult to write without specially-crafted routines, making disk copies difficult.

Bootstrap Code Disassembly

A disassembly and analysis of the 256-byte bootstrap routine is fascinating. Starting with literally nothing, this code must bang directly on soft switches to control the stepper and read the shift register. It must activate the stepper electromagnets in the right pattern to reach track zero, and then begin reading bytes. It must recognize the D5 AA 96 signature, and check to see if it has the right sector. It must use a GCR decode table which it constructs on-the-fly in order to convert disk bytes. It must perform 6-and-2 decoding to reconstruct three logical bytes from four disk bytes, load the whole sector into a RAM buffer, and then jump to the just-loaded code. And all of this in only 256 bytes!

Woz gets the job done with five bytes to spare, and only about 100 lines of 6502 assembly code. But due to space constraints, some features were omitted. The Disk II controller bootstrap code doesn’t verify the checksum on sector 0, something that was “fixed” in later disk controllers but caused incompatibility with some games. There’s also no error handling, so the bootstrap code will keep trying forever to load sector 0. This explains why an Apple II with Disk II controller card appears to hang during booting if there’s no disk in the drive, or a bad disk, rather than show a nice error message like the Apple IIc or IIgs.

Disk II Controller Hardware Design

This discussion has focused on what the Disk II controller does, without going into much detail about precisely how it does it, and how those eight chips are used. For an excellent and very thorough breakdown I recommend reading Chapter 9 of Understanding the Apple II by Jim Sather. It goes into additional detail about the flux patterns on the disk and much more.

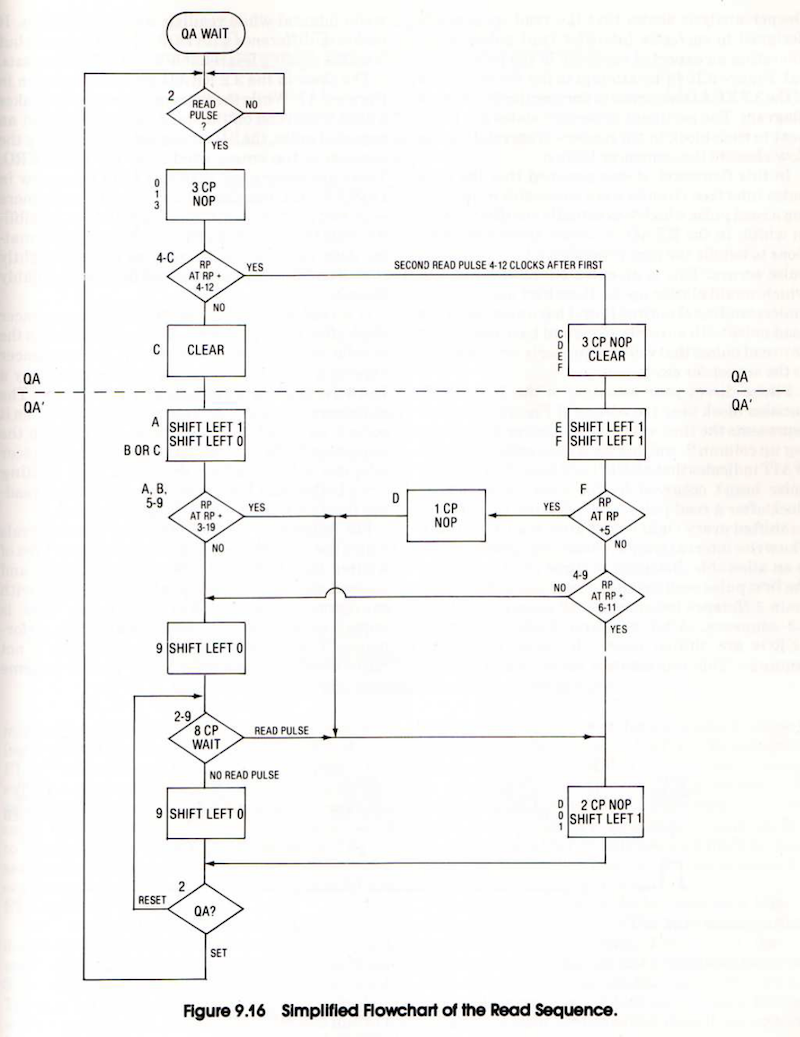

The design of the state machine is quite interesting, and I haven’t seen it described anywhere other than in Sather’s book. Anyone who remembers concepts like Mealy and Moore state machines from a long-ago class will recognize Woz’s work. The state machine ROM is just a simple lookup table. Its inputs are the current state, the read/write mode, the MSB of the shift register, and the next bit coming from the disk. The outputs are the next state and a set of control signals. Depending on the control signals, the state machine may shift the value in the shift register and append a zero or one bit, or clear the shift register, or parallel load the shift register from the data bus.

The state encodings are carefully chosen such that state bits can double as control bits. For example, when writing data to the disk, the value on the write head is also the most significant bit of the current state number. When reading data from the disk, the state sequences are chosen so as to frame pulses corresponding to 1 bits into an appropriate 4 microsecond window, and insert zero bits whenever 1.5 bit windows (6 microseconds) have elapsed without seeing a pulse. For my Yellowstone FPGA-based disk controller I’ve implemented the equivalent functionality in a hundred lines of Verilog; Woz did it with a 256-byte ROM and a hex flip-flop.

Putting It All Together

The words “software-driven” have come up again and again here, and that’s the theme of the Disk II controller. It enables a very flexible design using minimal hardware, but it pushes a tremendous amount of complexity onto the software. Modern software designers might call this bad practice, and would prefer to see that complexity abstracted away behind a standard interface, so the software only has to be concerned with actions like “read block 31”. And that’s exactly how all other Apple II disk controllers work. But in order to work with a Disk II controller, software like DOS 3.3, ProDOS, and most games need to include tons of extra code for manipulating the stepper, locating sectors, performing GCR decoding, and the whole kitchen sink. It’s a little bit crazy, but it works.

If you’ve read this far, you may be interested in the BMOW Floppy Emu disk emulator. Collectors of old Apple II, Macintosh, or Lisa computers will find the Floppy Emu invaluable for running software downloaded from the web, and transferring files between vintage and modern machines. The Floppy Emu stores hundreds of disk images on an SD memory card, and uses custom hardware to mimic many different kinds of Apple floppy disk drives and hard drives. Read more about it here.

During the 10+ years I’ve spent delving into every aspect of Apple’s disk drive designs, it’s been a remarkable journey. Years ago I used to think I understood how it all worked, but today I realize I hardly knew anything at all. Now I believe I’ve got everything mapped out, but of course there are probably still holes in my understanding that I’m blind to. Did I explain anything incorrectly here, or forget to mention something important? Let’s hear about it. Please leave a comment below.

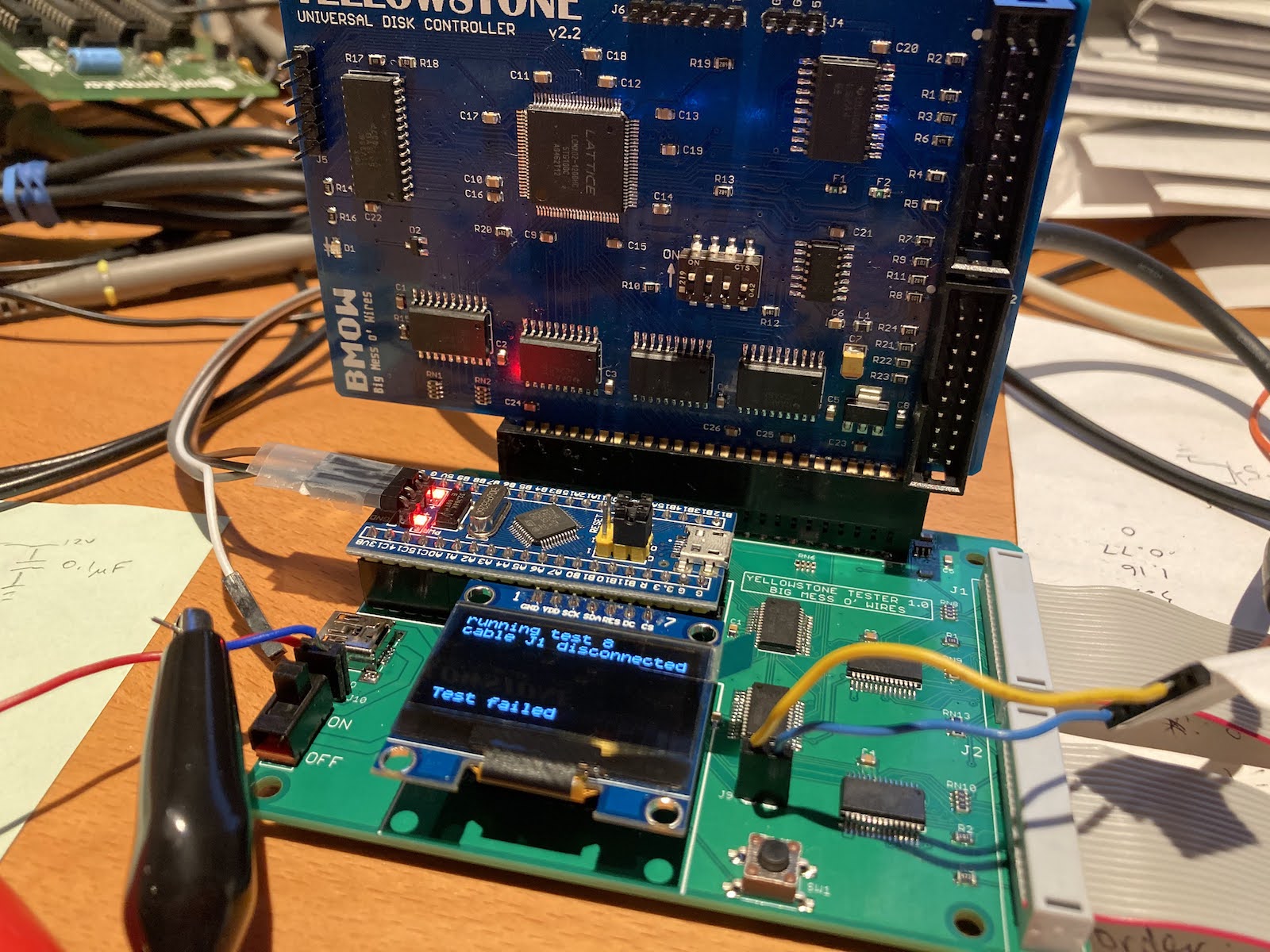

Read 10 comments and join the conversationCall For Yellowstone Beta Testers

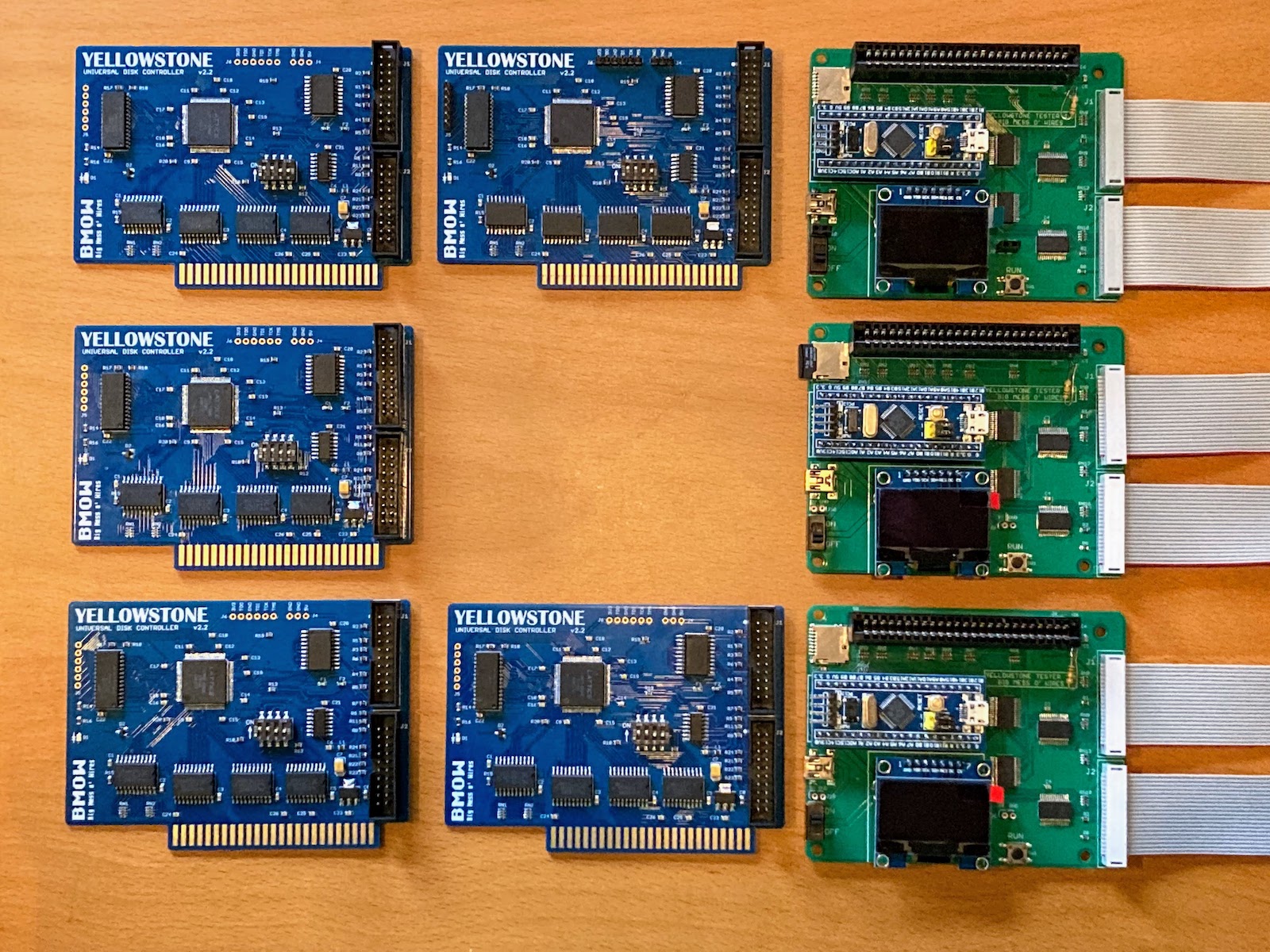

Here we go! Beta testing kicks off today for the Yellowstone universal disk controller for Apple II. Yellowstone is a replacement for the Liron disk controller, the Apple 3.5 disk controller, and the standard Disk II controller, all rolled into one. It even handles Macintosh disk drives. After a soldering marathon this week, I now have five working Yellowstone boards and three working Yellowstone testers. All the testers work with all the boards. The ducks are finally in a row. Let’s do this.

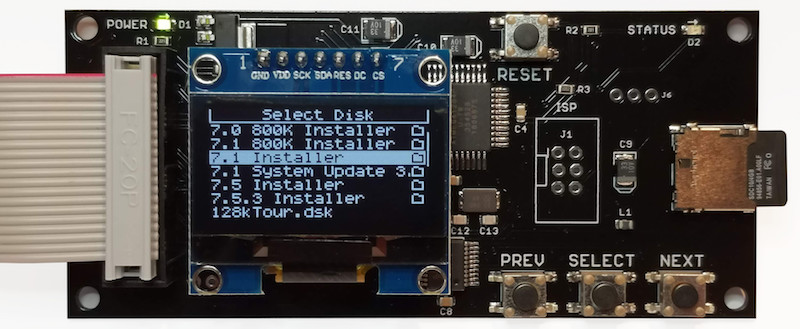

Before jumping into beta testing specifics, some readers may be curious to know how the Yellowstone tester turned out. The goal of the tester is to program and verify a newly-assembled Yellowstone board, as quickly and easily as possible, without requiring any other equipment. The tester development proved to be a major project in its own right, and occupied most of my available time for the past couple of months, but I’m happy to say it’s finally working. Here’s a video demonstrating the tester operation:

Calling Beta Testers

I need your help! I’ve tested the hell out of Yellowstone, but I won’t be truly confident it’s ready until it’s passed through other people’s hands, with other types of computers and disk drives, and other software environments. That’s where you come in.

The ideal Yellowstone beta tester will have:

- at least 5-10 hours available for testing in the next two weeks

- a personality that enjoys making lists, spreadsheets, and similar record-keeping

- a variety of Apple II computers and disk drives, especially an Apple II+, Duo Disk, Unidisk 5.25, Apple SuperDrive (FDHD Drive G7287), third-party 3.5 inch drives from Applied Engineering / Chinon / Laser / American Micro Research, and CPU accelerator cards.

I need to be slightly picky about who gets these beta cards, since I only have a few of them. The cards should go to people who are in the best position to help with testing, either by virtue of the hardware they have or the energy they’re willing to put into methodical testing. If this appeals to you, please get in touch with me using the Contact link at upper-right of the page, and let’s talk! If you’re more interested in Yellowstone for personal use and you aren’t sure you’ll have time or energy for beta testing, you’ll have an opportunity to get one soon when they become generally available.

What You’ll Get

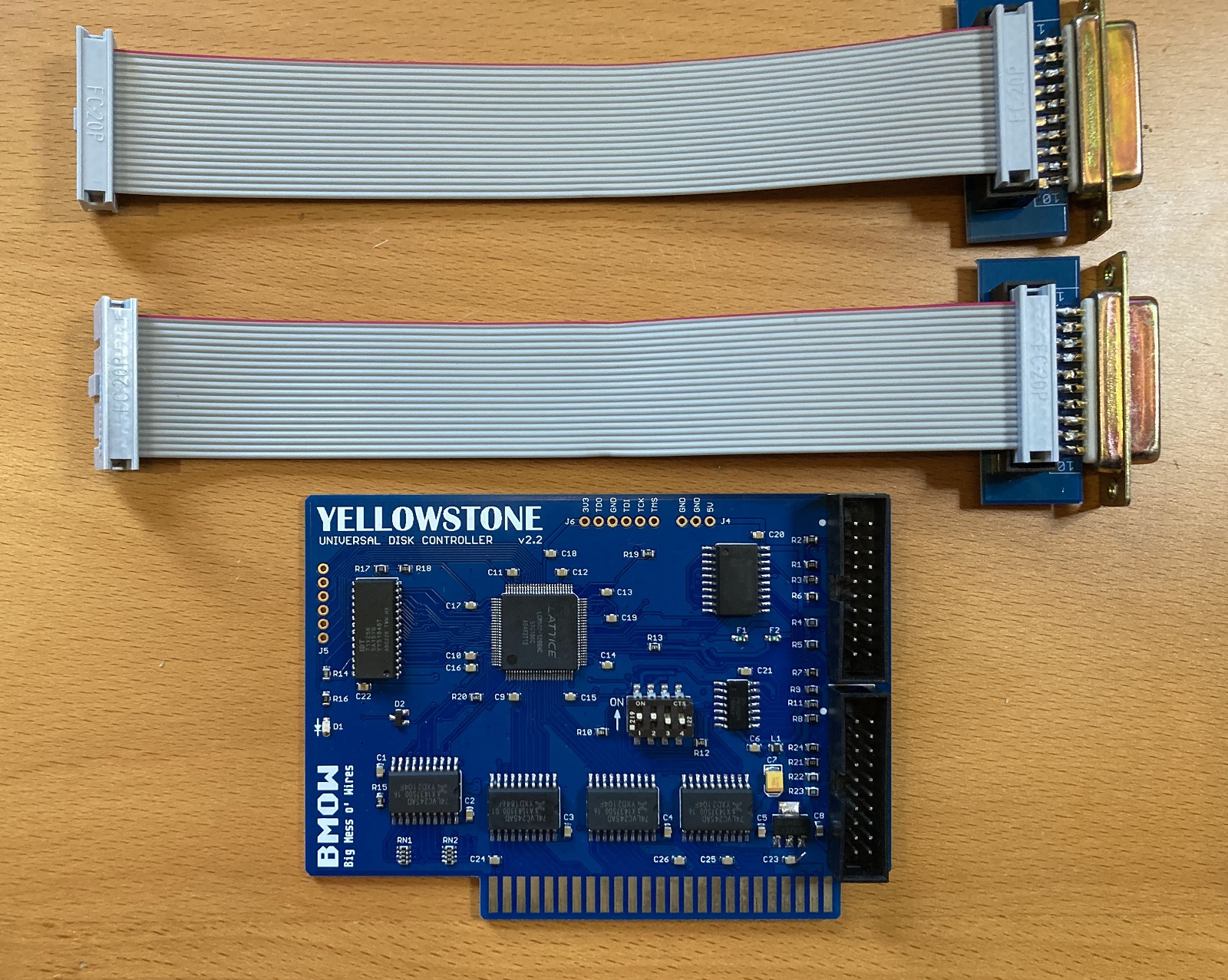

The draft instruction manual for Yellowstone offers a good overview of its capabilities. In brief, any type of Apple II or Macintosh floppy drive from the 1970s – 1990s should work with Yellowstone, as well as intelligent Smartport-based hard disks such as Floppy Emu’s Smartport HD emulation mode. It supports two drives of different types connected at the same time, or up to five drives for intelligent Smartport devices. Drives with 19-pin D-SUB DB-19 connectors and 20-pin rectangular connectors are both supported.

For the beta testers, I will also be including a pair of DB-19 female adapters. These will probably be a separate accessory when Yellowstone goes on sale, since not everyone will need them, and the DB-19 female connectors are rare and somewhat expensive. You’ll need these DB-19F adapters when connecting drives like the Duo Disk, Apple 3.5, or Macintosh M0131. The adapters aren’t needed when connecting a Floppy Emu, a Disk II, or internal / bare drive mechanisms using a ribbon cable with a 20-pin rectangular connector. The wiring of the DB-19F adapters is designed only for use with Yellowstone, so don’t try to connect them anywhere else.

I think that’s everything, and I’m very excited to be launching the Yellowstone beta today. Thanks in advance for your help, and don’t hesitate to contact me if you’re interested in being a beta tester.

Read 9 comments and join the conversationZener Regulator Trouble

In my attempts to resolve some logic level problems with the Yellowstone Tester, I decided to take a crude approach, and reduce the 5V supply to about 4.7V using a simple zener diode voltage regulator. From my previous tests with a variable voltage supply, the reduced voltage at 4.7V was enough to get the tester working nicely. But now when I try combining a fixed 5V supply with a resistor and a 4.7V zener, I find that it doesn’t work as expected. Zener regulators apparently don’t behave the way I thought they did, and for this specific circuit, they may not work at all.

The problem is that the rated voltage of a zener diode is only valid for a specific level of current. I knew this, but I thought the voltage would only change a small amount over a wide range of current: perhaps 100 mV of change for the 10 mA to 100 mA range where my circuit operates. In other words, I thought the IV curve for the zener would be very steep, nearly a vertical line.

This proved to be a bad assumption. Using a 1N4732A zener, at a current of 90 mA I do see 4.7V on the zener, but the voltage is only 4.506V at 40 mA, 4.459V at 30 mA, 4.335V at 20 mA, and 4.212V at 10 mA. That’s not good. It’s non-linear, but if it were a resistor then its value would be about 6.1 ohms. I’m not sure how I was meant to know this from the datasheet, which doesn’t include any IV curves. The datasheet does include a dynamic resistance (impedance?) number, but I thought that was for AC applications since it’s specified for a frequency of 1 kHz.

Voltage Regulator Says What?

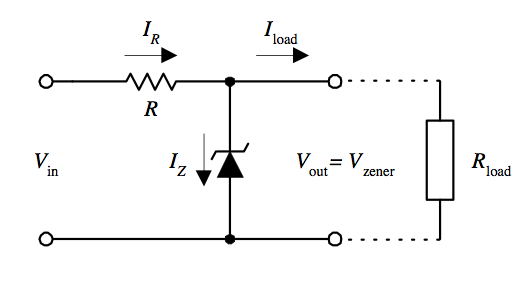

So how are you supposed to build a voltage regulator using a zener with this amount voltage of variability? The standard way to build a zener regulator is with a resistor in series with a zener, and a load in parallel with the zener:

If Vout is ever higher than VZ, then the zener will pass more current, which also increases the current through the resistor, which increases the voltage drop across the resistor and lowers Vout. So Vout gets “regulated” to the value of VZ, so long as the current through the zener remains constant.

If the circuit has a fixed load, then the value of the resistor can be chosen to get the desired current through the zener to achieve the nominal zener voltage. But if the circuit has a variable load, there’s a problem. In order to maintain a regulated output voltage, the voltage drop across the resistor must remain unchanged while the load current changes. That means the current through the resistor must also remain unchanged. The only thing that will change is how much current flows through the load and how much flows through the zener. If the load draws less current, then the zener must draw more, in order to keep the total current constant.

Let’s say the load current can vary between 10 and 100 mA, and the zener can theoretically handle 150 mA before it burns up. For safety’s sake you probably don’t want to push the zener all the way to 150 mA though, so you might limit it to 120 mA. You could choose a resistor value to achieve a constant current of 130 mA through the resistor, which can be divided between the zener and the load 120/10 mA for light loads anywhere up to 30/100 mA for heavy loads. That’s a 90 mA range of currents through the zener, so for a 6.1 ohm equivalent resistance you would see a 0.549V change in the output voltage. That’s not very well regulated at all.

If I’ve analyzed this all correctly, then a zener voltage regulator basically doesn’t work unless the load current never varies by more than about 10 to 20 mA. That’s a pretty lousy regulator. I’m not sure how I never realized this about zener regulators before.

Plan C

So now what? I still need to get the Yellowstone Tester working. The original 5V circuit has problems with the logic levels, and Plan B for reducing the supply voltage to 4.7V with a zener seemingly doesn’t work either. Would I be better off with a simple Schottky diode in series with the 5V supply input? This wouldn’t be perfect either, since the nominal 5V supply might actually be closer to 5.1V or 4.9V, and the voltage drop across the diode will change with the load current. But I still think it would be enough to keep the voltage within a range of about 4.8V to 4.5V, which is better than I’ll get with the zener.

Read 7 comments and join the conversation5V Logic Level Errors

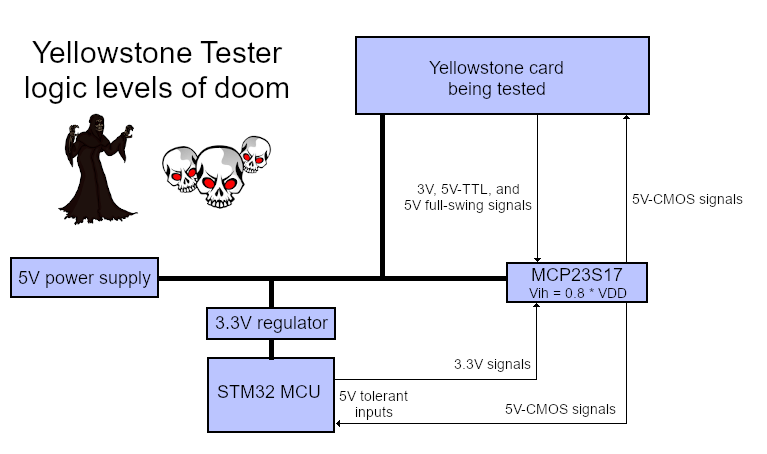

The Yellowstone tester is suffering from the logic level blues. I made a blundering error in its design, which I only discovered now. Like most of my projects, the tester uses a mix of voltages, with the MCP23S17 port expanders running at 5V while the STM32 microcontroller and everything else are running at 3.3V. The card being tested is nominally a 5V device, but it uses TTL signal levels where anything above 2V is considered a logical “1” value. This whole menagerie seemingly worked fine during the tester’s prototyping and development, but it actually has some major problems.

The relevant pins on the STM32 are 5V-tolerant, so that part is fine. Unfortunately I failed to check the input voltage thresholds on the MCP23S17. Now I see that it requires a voltage of at least 0.8 * VDD to detect a logic “1” input value, which means a threshold of 4.0V when VDD is 5V. The STM32 signals are never going to exceed 3.3V, so that’s no good. The so-called 5V signals from the card being tested mostly won’t reach 4.0V either. Some of those signals are driven by 74LS logic with typical high values about 3.4V, and others by 3.3V 74LVC devices.

I’m slightly amazed that I completed the tester prototype, tester PCB, and development of all the tester software without discovering this glaring problem. In fact just yesterday I’d privately declared the tester to be “done”. It was working well, able to program a virgin Yellowstone card and run a large series of functional and electrical tests in just a few seconds’ time. Aside from some rare flakiness I couldn’t reproduce, everything looked good. But then I tried using a different power supply and everything fell apart.

How Did This Ever Work?

With the aid of an adjustable power supply, I eventually found that the tester worked reliably at supply voltages up to 5.05 volts. Above that, the STM32 was unable to communicate with the MCP23S17 port expanders. Some of my other power supplies produce about 5.08 to 5.1 volts with a light load, so that explains why they didn’t work. With a higher VDD, the logic “1” input threshold of the MCP23S17 is also higher, creating a larger shortfall for 3.3V or 5V-TTL signals.

It’s surprising that this ever worked at all. Even at precisely 5.0V, the best case would be a 3.3V signal from the STM32 going into a MCP23S17 input with a 4.0V threshold. A shortfall of 0.7V is pretty large. And yet it did work nicely, at least in this particular circuit, over several weeks of tester development.

Choosing a Voltage

The MCP23S17 port expander can operate with a supply voltage of 5V or 3.3V; I intentionally chose 5V here because the chip interfaces with a card being tested that’s nominally a 5V device, and I was worried about damaging the MCP23S17. Even though most of the output signals from the card should be lower-voltage TTL-level logic signals, at least some of the signals may truly be 5.0 volts. And if the card is defective, which is part of what the tester needs to determine, then any of the card’s signals could be unexpectedly at 5.0V. A chip that’s running at 3.3V can be damaged if 5V is applied to an input pin. If the MCP23S17 has 5V-tolerant inputs then it would be OK, but sadly it doesn’t, so I need to run the chip at 5V to safely read 5V signals. (Probably. See below.)

You can view the MCP23S17 datasheet for the details. In the section for Absolute Maximum Ratings, it says the voltage on all pins should not exceed VDD + 0.6V, and the input clamp current when Vi > VDD should not exceed 20 mA.

How Do I Fix This Mess?

The tester isn’t a product, it’s a tool for developing a product – the Yellowstone disk controller card. I only plan to build three or four testers, and they’ll all be in my possession, or given to whatever PCB assembler I choose to work with. That means I can consider some unconventional fixes here that I would never do on a mass-produced product. If at all possible, I’d like to fix this with some minor surgery to the tester PCB. I really don’t want to design a new tester PCB, add more components and level-shifters, etc. But I need to be confident that the tester is reliable, and if I give one to a PCB assembler, it can’t flake out or give false positives due to minor variations in supply voltage, temperature, or parts substitution on the card being tested.

The fundamental problem is the gap between the 4.0V logic “1” voltage threshold required by MCP23S17, and the lower voltages produced by the STM32 and the card being tested. I either need to raise those voltages up, or lower the MCP23S17 threshold down. None of the possibilities look very promising.

Raising up the lower voltages is basically out of the question. They are what they are, and it would be painful and impractical to insert 5V level shifters on 80-some signals from the card and the STM32.

Lowering the threshold is the only plausible option, which means lowering the supply voltage of the MCP23S17. How much should I lower it, using what method? What other problems might this cause? Should I also lower the supply voltage for the card being tested?

I could lower the MCP23S17 threshold by changing the chip to use a 3.3V supply instead of 5V. But then I would create a new problem where 5V signals might be applied to the chip running at 3.3V, exceeding the absolute maximum rating of VDD + 0.6V and potentially damaging the chip. I could possibly put a series resistor on each of the pins, in order to keep the input clamp current under 20 mA, although this would create some other difficulties and would require making a new PCB.

If I also reduced the supply voltage for the card being tested to 3.3V, it would eliminate the over-voltage concern, but a Yellowstone card won’t work correctly at 3.3V. It has a 74LS244 chip, with a minimum supply voltage of 4.5V.

Diode To The Rescue?

There are no great answers here, but the most promising option I can think of is reducing the supply voltage for the MCP23S17 and for the card being tested to about 4.6V. Using the same voltage for both means there’s no over-voltage risk. At 4.6V the Yellowstone card should still work OK. The reduced voltage would lower the MCP23S17 input threshold to 3.68V, which is still too high, but my tests with the actual hardware show that it should work anyway. The hack-tastic way to get about 4.6V from a 5V source would be using a Schottky or germanium diode to drop a few tenths of a volt. This would be fairly simple to do.

Alternatively I could run the card at 4.6V, but lower the MCP23S17 supply even further to 4.2V, using a second diode. This would still be within the MCP23S17’s absolute maximum rating of VDD + 0.6V, so there shouldn’t be an over-voltage risk so long as the voltages don’t vary too far from their expected values. With a 4.2V supply, the MCP23S17 input threshold would be reduced to 3.36V, which is close enough to 3.3V that I’d be more confident in its reliability.

Complicating all of this is the presence of a 1 ohm sense resistor on the tester’s power supply, which is used for current measurements. Under normal operation, this drops about 50 to 100 mV. If the power supply is nominally 5V, then the MCP23S17 and the card being tested will see a voltage closer to 4.9V.

Another complication is that the 74LS244 on the card being tested will output 5V TTL signal levels, and according to its datasheet, its logical “1” output voltage may be as low as 2.4V. I can’t reduce the MCP23S17 supply voltage far enough to support an input threshold that low. But in practice for a correctly-operating Yellowstone card, and the tester circuitry that’s connected to it, the 74LS244 voltage should be closer to 3.0 – 3.5V, similar to the voltages from the 3.3V STM32.

Using a diode to create intermediate supply voltages is a gross hack, and I don’t like it. It might work during my desk experiments, but then fail later in a different environment. And yet I’m not sure what better alternative I have, unless I’m willing to make major modifications to the tester that will set me back by several weeks. The choices all look bad. I’m embarrassed that I made it this far into tester development without noticing such a fundamental design error.

Read 5 comments and join the conversationThe Yellowstone Tester

I once said I’d spend a maximum of one day on development of an automated tester for the Yellowstone disk controller. Haha, that was so cute. Today marks two months since I began work on the tester. Today was also the first try with the final (I hope) tester hardware. So far it seems to work, mostly.

Yellowstone is an FPGA-based disk controller for Apple II computers. It’s complex enough that fully testing each board is a non-trivial task. Manually testing a large batch of boards would be out of the question, so an automated tester is needed. The heart of the tester design is an STM32 “Blue Pill” board, combined with four Microchip port expander chips to reach a total of 80 I/Os. There are also a few analog sensors for measuring current and voltage, as well as a current switch IC that will disconnect the board being tested if it draws too much current.

Unexplained Current Changes

The ability to measure the supply current was one of the key features of the tester design. Unfortunately it doesn’t seem to work as well as I’d hoped. I was convinced that I needed to measure the combined supply current of the board being tested and the tester itself, in order to capture all possible paths where a short circuit might occur, and that works. So far, so good.

The odd thing is there are unexplained fluctuations in the measured current. With no Yellowstone board present, the current sensor reports about 26 mA used by the tester itself. But if I write some code that sits in a loop repeatedly measuring the current, but doing nothing else, sometimes the current briefly jumps up to 35 or 40 mA. This happens roughly once every second, but not consistently enough to make a reliable pattern. With a Yellowstone board present, the current is higher but similar current measurement fluctuations are still happening. At first I thought this was some deficiency in the STM32 ADC, but other analog measurements by the STM32 don’t have the same issue.

I’m not sure if these current changes are real, perhaps caused by some internal activity of the STM32 briefly increasing the supply current, or if the changes are somehow an artifact of how I’m measuring. Either way, the fluctuations are large enough to undermine most of what I’d planned to use the current measurements for. A measure of 70 mA +/- 25 mA isn’t accurate enough for much diagnosis beyond detecting a hard short-circuit.

Unresponsive ICs

A second problem I encountered is that the Microchip port expander ICs occasionally don’t respond to SPI commands. This often happens when I first turn on the tester after it’s been off for several minutes, but never happens when turning it briefly off and on, or resetting the tester while keeping the power on.

Surprisingly (or maybe it’s not surprising) there seems to be a relationship between the current fluctuations and the unresponsive port expanders. After the board has been off for several minutes, and is then turned on, I’ll very often see an immediate current fluctuation followed by unresponsive port expanders. I’ve added some code when the tester starts up that will repeatedly poll the port expanders until they respond as expected, and this appears to be working for now.

The tester PCB isn’t well designed for probing internal signals to see what’s wrong. Because I already built a breadboard prototype of the tester previously, and thought it was working, this new PCB was designed for small size rather than for debugging. It may require some fancy soldering and old-fashioned detective work to figure out what’s happening here.

Read 6 comments and join the conversationApple II Pascal Booting Problems

Thanks to beta tester Bryan V., I’ve discovered that Apple II Pascal disks don’t boot normally with the prototype Yellowstone disk controller card. This includes the Pascal master disk as well as other disks built on Pascal, including Fortran, “Apple at Work”, and the game Wizardry. These disks begin to boot normally, and several tracks’ worth of data are loaded from the disk successfully, but then they halt with an error like “SYSTEM.PASCAL not found” or “Insert boot disk with SYSTEM.PASCAL”. These same disks work OK when Yellowstone emulates a plain Disk II controller card, so it looks like a ROM/software issue rather than hardware. For what it’s worth, a Laser UDC card also shows the same problem when attempting to boot these same Pascal disks.

The behavior is strange, because for every other disk I’ve seen with a ROM dependency on the Disk II controller card, it crashes or freezes during boot when it tries to use the missing Disk II controller card ROM. But the Pascal disks are failing with a nice error message about a missing file, making me think the problem is probably something else.

One clue: I found three Pascal-based disks that fail to boot even with a real Disk II controller card, on an enhanced //e: Pascal 1.1 Apple0 680-0003-01.dsk, Apple Pascal Basics and Integer & Applesoft II, and Pascal Profile Manager. I’m unsure if there’s a missing hardware requirement or if I’m doing something wrong. Even with a standard Disk II controller card these disks halt with the messages “No file SYSTEM.APPLE”, “Insert BASIC disk and press any key”, and “Insert boot disk with SYSTEM.PASCAL”, respectively.

I’m not very familiar with the low-level details of Apple II Pascal disks, or how Pascal does disk I/O. Maybe it expects a different set of API entry points in the disk controller ROM than ProDOS? Or maybe there’s something else unique about its disk I/O behavior?

The good news is that these Pascal-based disks do work OK when Yellowstone is configured in its Disk II controller emulation mode, but I’d like to understand why the normal Yellowstone mode doesn’t work.

Read 11 comments and join the conversation