Archive for the 'Business' Category

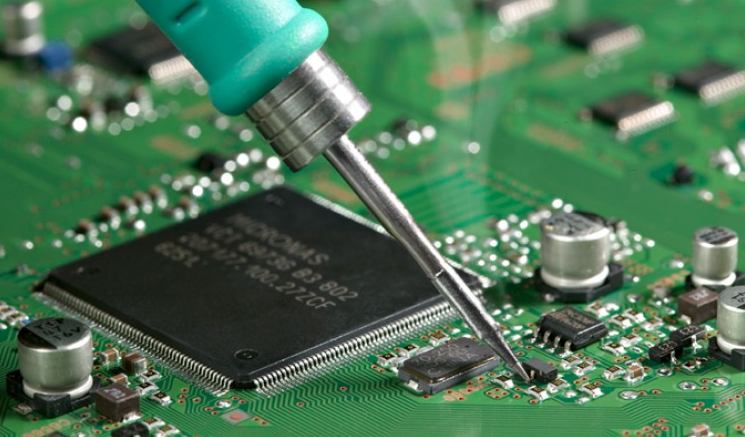

Outsourced PCB Assembly and Testing

Help request! If any reader has experience taking a hobby-scale electronics project to an outside vendor for assembly, I’d love to hear from you. I’ve been talking with the fab in China that makes the Floppy Emu PCBs, and they can do the full assembly process for a reasonable price. That means making the PCBs, ordering all the components, and doing 95% of the assembly. I’ll add the DB-19 connector and LCD myself. But I’m stuck on determining what kind of testing to request from them, if any. It seems like a simple question, but I don’t have the experience to know what kind of failures to test for or what failure rate is typical.

The vendor will send me hardware that passes whatever tests I specify. If a board fails a test, it’s up to them to find out the problem and fix it. Ideally they’d do a full functional test – the same test I do before shipping a Floppy Emu – but that’s not practical for several reasons. I’d have to ship several vintage Macs to Shenzhen, and give them instructions on how to use old System 2.0 software and perform a non-automated series of file copy tests. Assuming they were even willing to do this, it would be expensive and time-consuming, and I’m not sure I’d even trust them to do it correctly.

At the other end of the spectrum, they could do a basic power-on test. Apply power, and confirm that the power LED turns on. But that wouldn’t really prove much except that there are no power-to-ground shorts. There could be all kinds of horrible problems with the board, but the LED would still turn on and the test would still pass. Furthermore, it’s not so easy to “power on” a Floppy Emu without having a Mac, since it’s meant to be powered through the floppy port. I’d have to build them some kind of power adapter, or they’d need to connect test leads to specific pins on the board to power it.

A mid-level test would be for them to flash the AVR firmware, then confirm that the status LED blinks three times at power-on (the normal behavior). That would at least show that the AVR was working correctly. But it wouldn’t do anything to test the SD card interface, or the CPLD, or the LCD interface. And there would still be the same challenge of powering the hardware without having a Mac to connect with it.

What makes this difficult is not knowing what kind of failure rate is typical, nor what kind of failures. If I specified no tests at all, and they installed an IC backwards in all the boards, I could get a 100% failure rate. Would something like that be my responsibility, or theirs? If I didn’t provide any tests at all, they could theoretically send me anything and have still met their obligation.

Lastly, the cost of testing time is somewhat expensive relative to the cost of the hardware. For a run of 50 units, for each 1 minute per unit spent on testing, it’s the same cost as if they did no testing and 1 unit was defective and discarded. For example if they spent 5 minutes per unit on testing, I could afford to have 5 of the 50 units be defective and unusable – a 10% failure rate – for the same cost. Since 5 minutes of testing still wouldn’t guarantee a 0% failure rate anyway, the cost of testing begins to look questionable unless the typical failure rate is high.

Working out testing details with someone who’s on the other side of the planet and who’s not a native English speaker can be difficult. I tried to find an electronics assembler in the United States, but had terrible results. One place actually contacted me, after reading the blog, but they later said they couldn’t handle my order and referred me to a second US vendor. I contacted the second vendor, but they never responded. A third US vendor was referred to me by a friend of a friend. I sent them a detailed description of the project and some questions about their process, but heard nothing for more than a week. Finally they wrote back with a generic reply, without quoting any price or answering any of the questions I’d asked. A fourth US vendor was referred to me by another retro-computer enthusiast I know, but so far I’ve had no response from that vendor either. In contrast, the Chinese shop sent me a detailed quote within 24 hours of my first inquiry, and was happy to have my business.

In a perfect world I’d have a test that was easy to run, quick, required no extra equipment, and could catch near 100% of the possible problems. But I don’t have that, or even anything close. So I’m leaning towards no testing, but my nightmare scenario is to spend lots of money and receive 50 units that are all broken, due to some kind of systematic assembly problem.

Has anyone else been through this process before? What was your experience?

Read 8 comments and join the conversationSupply Chain Snafu

Where and how do you find the parts needed to build your hardware? Selling Floppy Emu on a small scale has introduced me to the difficulties of managing a supply chain, and I’ve discovered it’s more difficult than it looks. Doing it wrong means higher costs, more risk, and a danger of running out of key parts at the wrong time. Due to my own poor planning, Floppy Emu has been stuck at “out of stock” for far too long, and I can’t even say for certain when it will be back.

Choosing a vendor from whom to buy parts seems like it should be easy: just use a search engine like Octopart to find the vendor with the lowest price. Sadly it’s not that simple. Some guy on eBay may have the lowest price, but how can I know if his parts are good quality, or if they’re recycled, relabeled, or even counterfeit? Is the savings enough to be worth the risk? And then there are “overstock” vendors like Arrow, Avnet, and Verical, who often have very good prices but require minimum orders of 100+ parts. Are they worth it?

Even if it’s clear which vendor is best for a specific part, it becomes less clear when all the parts are considered together. Floppy Emu is built from about 15 different types of parts, and if I ordered each one from a different vendor, the combined shipping costs from all those vendors would kill me. It’s a balancing act, and it’s often necessary to buy a part from a vendor whose price isn’t the best, so I can combine it with other parts in the same order from that vendor.

Mapping all this out is a pain, but at least it only needs to be done once, right? Wrong. The vendor prices are constantly changing, and less commonly the minimum order sizes change as well. So every time I go to order more parts, I have to start the analysis over again.

I struggle the most with determining how many parts to order. Virtually every vendor has a sliding price scale, where the per-part cost decreases as the number of parts ordered goes up. So there’s an incentive to make orders for large numbers of parts to drive down the average cost, but there’s also a risk. If I order 100 ATMEGA1284 microcontrollers, and then interest in Floppy Emu dries up, I could be left with $1000 worth of useless chips sitting on a shelf. But if I order them 10 at a time, I’ll not only be paying more per chip, I’ll also be reordering nearly every week and risking running out of parts if demand temporarily spikes up.

Out of Stock

My current problems are due to Floppy Emu’s LCD display. In mid-January I thought I had two boxes of LCDs remaining, when in reality I only had one. When I discovered the truth, I only had about six LCDs left. I placed an order for more LCDs on January 29, from the same Chinese vendor I’d used in the past. But then Chinese New Year hit, and nothing happened for a week. The package finally shipped on February 6. Meanwhile, I ran out of LCDs on February 8 and put Floppy Emu into “out of stock” status.

My last order from this vendor took 10 days to arrive from China, so I expected the new LCDs to appear around February 16. But that day passed with nothing in my mailbox, nor the next, nor the next. Time ticked by. As I waited, I accumulated enough Floppy Emu back orders so that the new supply of LCDs would already be nearly exhausted by the time it arrived, so I placed a second order for even more LCDs.

When I checked back on the first order, I saw the vendor was now quoting 25 to 30 working days for delivery. What?! That’s like a month and a half! I’m not sure if this was a change in policy, or the 10-day delivery time I had earlier was just an outlier, but they were now giving me an estimated delivery date of March 7-15. Somehow the second LCD order was estimated to arrive earlier, on February 28 to March 6, despite being ordered three weeks after the first LCDs and being shipped by the same method. And there’s no tracking info on either shipment, so there’s nothing to do but wait.

Read 8 comments and join the conversation

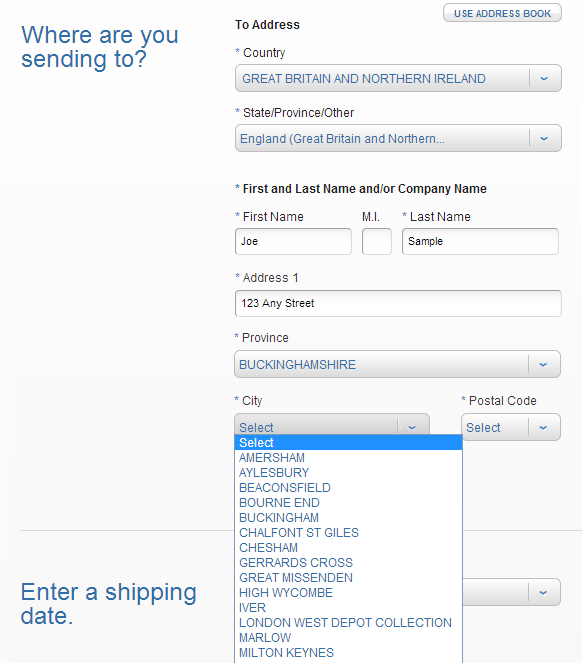

International Shipping Meltdown

US Post Office, what are you doing to me? The USPS Click-n-Ship service has always been cumbersome, but it’s the only practical way to mail packages outside the USA via First Class Mail, which is the only way to send packages economically. Over the weekend the post office revamped the site, and now I’m unable to send any packages by First Class Mail. This leaves me with a choice between increasing my international shipping fee by 2x, or withholding all international shipping until some other solution is found. At the same time, the post office changed the method of address entry for most countries, so it’s no longer a free-form text entry, but a series of drop-down menus. If the city or postal code in your package’s address isn’t one of the choices provided, too bad.

In last month’s rant about international shipping headaches, I mentioned some of the problems I’ve encountered. Addresses must be formatted a particular way, regardless of whether that’s how they’re normally formatted in the destination country. Only numbers or the 26 letters from A to Z are permitted in the address. If the address is supposed to contain an accented letter, or any non-Roman letters like something from the Japanese or Korean alphabets, too bad. This is the US Postal Service. We don’t do accents.

The recent move to drop-down menus for composing the address makes matters even worse. Today I tried to send a package to the UK: destination Uxbridge, London, UB11 1BB. Look at the screenshot above, and you’ll see that I’m required to select a province before I can fill in the rest of the address. I wasn’t aware the UK even had the concept of provinces. So what province is London in? Ummm, England? Nope, that’s not a choice. Let’s see, British geography quiz, this should be fun. According to the post office, the city of London is in the province of… London! But then I had to choose a city (which should be obvious), given a list of 10 choices including “London”, “London West Depot Collection”, “Finchley Road”, and “Westminster”. Ugh. And no matter which one I chose, UB11 1BB was never offered as a choice for postal code. Total failure. I simply cannot mail a package to this address, using this service.

Then I discovered that the interface for choosing the shipping method has also changed. It used to be that you’d enter the package address, then on the next page you’d see a list of shipping methods including First Class, Priority Mail, and Priority Express. Now it’s a Javascript-enabled form that dynamically changes to show you the applicable shipping methods for the address as you type it. At least that’s the theory. In practice, it only ever shows Priority and Priority Express as choices. At first I thought this might reflect a change in policy for international shipping, but then I discovered that the same problem occurs when printing postage for domestic packages. RIP, First Class Mail?

I went to the local post office, waited in line, and spoke to an employee who assured me that First Class International was still a valid shipping method, and she was able to send the package to London UB11 1BB without problems. But it required almost an hour of my time, driving to the post office, waiting in line, and filling out custom declaration forms by hand, and it also cost 10% more than purchasing the same postage online by Click-n-Ship used to.

I’m not sure the best way to get this resolved. I tried Click-n-Ship’s live support feature, but got a generic error asking me to try again later. I spent an hour on hold waiting to talk to tech support before hanging up in frustration. Under the theory that maybe it was a browser bug, I tried Internet Explorer instead of my normal Chrome, but that didn’t help. Maybe there’s something about the address and package details I’ve entered that rules out First Class mail as a choice, so it’s never shown as an option? I don’t think so, though.

At this point, I think my only option is to hope that this is a bug and not a policy change, and hope that it magically gets fixed in the next few days. If not, I may have to start shipping international packages by Priority Mail, and charging substantially more for international shipping than I have been thus far. I sure wish the post office weren’t such an inscrutable bureaucracy, or that any of the other carriers like FedEx offered reasonably-priced options.

Edit: It looks like First Class International postage has been fixed! Thank you, USPS web programmers. My apologies to everyone who suffered through my rant. Now if I can only figure out how to ship to London UB11 1BB…

Edit 2: Choose “other” from the Province drop-down menu, then you can type in whatever you want without needing to follow the post office formatting.

Read 20 comments and join the conversationSelling the Floppy Emu

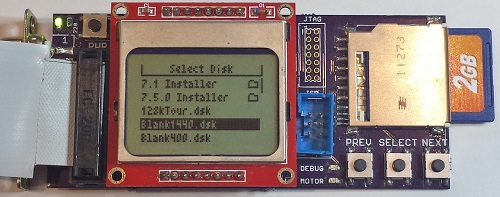

It’s been about a month since I began selling my Floppy Emu disk emulator for vintage Macs, and it’s time for a progress report. It’s been a real learning experience with the hardware, as well as on the “business” side of things. If you’ve ever considered turning a hobby project into a source of extra income, you may be especially interested in this side of the story.

The Biz

First, the business report: To date I’ve hand-built 44 of these little guys. 39 passed all my tests and received the seal of approval, for a yield of about 89%. Of the working boards, I sold 33, gave two as gifts, kept two for myself, and have two currently available for sale.

About half the Floppy Emus I’ve sold have gone to people outside the USA. Initially this surprised me – I’m in the USA, and I assumed most of the readers of my blog were too. Then there are large chunks of the world where the Mac was never popular, which are effectively ruled out as potential customers. And because the blog is in English, potential customers are further limited to those who are comfortable enough with the language to follow along. Yet despite all this, there are a surprising number of die-hards in Slovenia, Brazil, and other unexpected places who are buying Floppy Emus. Hello! So if you’re in the United States and considering selling some kind of DIY product, don’t make the mistake of ignoring the international market.

For a while I was operating a waiting list, but it was a bigger hassle than it was worth. Only about half the people on the waiting list actually followed through to make a purchase once I told them their board was ready. It was also awkward to reserve units for people on the waiting list, who may or may not eventually buy them, when it meant there weren’t enough units for the people who came later and were ready to buy.

Assembly and Test

All the Floppy Emus are built by hand, by me, with a regular soldering iron. It’s a fairly labor-intensive process, and with orders averaging about one per day, it’s monopolized most of my free time for the past month. I’ve been building boards in small batches of three to five at a time, updating the stock on the web page as new boards become available. This has created a pattern where Floppy Emu is constantly going in and out of stock, and I haven’t yet been able to get far enough ahead to keep a steady stock available. I guess that’s a good thing as it means there’s demand, but it would be nice if I weren’t always on the edge of running out.

The 89% success rate is pretty bad. Or maybe it’s reasonable for a hand-assembled electronics item, but throwing 11% of the hardware in the trash is a frustrating and expensive way to do manufacturing. Not only do I lose all the money that went into those failed boards, I also lose the hours it took to assemble and test them. This is an area where I really need to improve. The defective boards failed in various ways that I couldn’t diagnose or repair. Some of them almost work, but exhibit occasional failures when reading or writing. Others are nothing but scrap.

I’ve looked into having an assembly shop build a batch of Floppy Emus, but I probably need to purchase 50 or 100 units at a time for it to be cost-effective. With a new manufacturer, there’s also a risk of some misunderstanding or error that would lead to delivery of 100 non-functional Floppy Emus, and I can’t afford that risk. There are also some elements that an assembly shop likely couldn’t accommodate with their standard process, like the edge-mounted DB-19 connector, and the LCD mounted on a separate module. So for the time being, Floppy Emus will continue to be hand-assembled.

Assembly is slow, and it’s not just the time spent soldering. Setting the AVR fuses, programming the chip, and adjusting the LCD contrast for each board takes a surprising amount of time. Just digging the next part out of the box eats a substantial amount of time too. With a dedicated work area I could leave all the parts laid out for easy access, but I have to get by with a small desk that’s also used for other purposes.

Each Floppy Emu is tested three times on three different computers: a 400K disk test on a Mac 512K, an 800K test on a Mac Plus, and a 1.4MB test on a IIsi. These aren’t just quick boot-up tests either: they’re read and write tests that fill an entire disk image, multiple times, using each of the two floppy connectors on the board. Each Floppy Emu goes through about 20 minutes of testing, but when testing multiple boards at once I can do one every 10 minutes with pipelining. That’s a lot of manual testing work, and it bloats the time per board beyond the actual assembly time. And of course if there’s a problem found during testing, more time is needed to troubleshoot and fix it.

Shipping and Handling

I used to think “handling” was just a bogus term used to rip-off buyers, but now I understand why the cost to ship something is not necessarily the same as the cost of postage.

For USA shipments, it takes me about 10 minutes to prepare one Floppy Emu to be mailed. How can it take 10 minutes just to put something in a box? I didn’t believe it myself at first, but I’ve timed myself doing it often enough to accept it. The buyer’s contact info needs to saved, so I can contact him/her later if necessary. Then the Floppy Emu has to go in an anti-static bag, and the bag gets sealed. I have to assemble a box, fill it with foam peanuts, wrap the anti-static bag in bubble wrap, and cradle it in the peanuts. Then I need to print a packing slip and an instruction sheet, stuff those in the box, close it up, and seal it all with packing tape. Then I need to feed a sheet of label paper into the printer, log into the PayPal web site, purchase and print the postage, and stick it on the box. I have newfound sympathy for mail room employees.

For shipments going outside the USA, it takes about 15 minutes to prepare one Floppy Emu for mailing. For unknown reasons, PayPal will not sell postage for International First Class mail. I need to log into a separate account at the US Post Office Click-n-Ship site, and copy the pieces of the address one at a time from the PayPal data to the Click-n-Ship page. Instead of a single blank field for the address, Click-n-Ship forces me to break it up into separate form fields for first name, last name, street address, city, postal code, etc. Often these don’t match well with the way addresses in other countries are formatted.

If any letters have accents, the form validation fails, and I have to reformat it manually. Méndez Núñez must become Mendez Nunez. Sorry. This reminds me of some traffic signs in the area of California where I live. Many local place names are Spanish, and some signs for Cañada College have it as Canada College. When I first moved to the area, I couldn’t understand why the nation of Canada was sponsoring a local school.

I discovered that shipping materials cost real money! For USA shipments I can use the free Priority Mail boxes, but for international mailing I need to buy appropriate boxes, which must be purchased 50 or 100 at a time. Anti-static baggies, bubble wrap, packing tape, and shipping labels all cost money too. I hadn’t really considered this when I did my original cost estimates.

Once everything’s packed and ready to go, I have to bring it to the post office for mailing, which is about a 20 minute errand round-trip. Sometimes I can combine it with another errand, but I often find myself spending 20 minutes in the car just so I can mail a single Floppy Emu package. Post-9/11 paranoia means we’re no longer allowed to put packages in neighborhood mailboxes, but must take them to the post office and put them in the mail drop there. For international packages, you’re not even allowed to use the mail drop, but must wait in line to hand the package to a retail employee in person, even if the postage was already purchased online. Fortunately my local post office workers don’t insist on this rule, and told me that putting international packages in the mail drop is fine.

Between testing, packing, and visiting the post office, I’m averaging at least 30 minutes of labor per Floppy Emu above and beyond the time it takes to actually build it. Combined with the costs of shipping materials, that’s a significant amount of overhead I hadn’t planned for.

Parts Sourcing

Getting the parts needed to build each Floppy Emu has proven to be more challenging than I’d expected. I’m buying most of the parts from DigiKey, but the prices are constantly fluctuating, and sometimes it’s cheaper to buy certain parts from another vendor. It’s a bit of a puzzle, every time I refill my supplies. For most parts, the unit price is substantially cheaper when buying many of them vs buying a single one. I’ve been buying the majority of parts 10 at a time, but vendors other than DigiKey typically have higher minimum orders or steeper discount curves that force you into buying large quantities. I had to buy 73 of those DB-19 connectors!

Two other parts costs I neglected to account for are shipping and sales tax. These two combined add about 20% to my total cost of parts. In theory I could avoid paying sales tax by showing the suppliers a sales tax exemption certificate, but that would involve a layer of government red tape I haven’t wanted to mess with yet. It would also mean collecting sales tax when a California resident buys a Floppy Emu, which is something I really should be doing anyway, but would be a pain in the butt.

I discovered another hidden cost of parts sourcing too, and it’s one that wasn’t obvious at first. Say I’m building widgets, and each one needs a sprocket and a lever. If I buy 50 sprockets for $4 each and 50 levers for $3 each, then my total cost of parts is $7 per widget, right? Well, not exactly. It costs $350 to buy 50 sprockets and 50 levers, and I won’t recoup that cost until I’ve sold 50 widgets. If I do this repeatedly, on average at any given time I’ll have the parts for 25 unsold widgets sitting on my shelf. That’s a cost of $175 that I’ll never get back unless I quit the business after selling some exact multiple of 50 widgets. It’s like a security deposit, or worse.

The Sincerest Form of Flattery

The last of the business surprises was the theft of the Floppy Emu name. Another person (or company?) in Europe has started selling disk emulators using the Floppy Emu name for their product. I won’t link to it and lend it extra page rank points, but you can find it if you try. As far as I can tell, it’s a PC floppy emulator and not compatible with vintage Macintosh computers, so it’s not going to accomplish much except for confusing people.

Biz Summary

If you’re getting the picture that there are a lot of unforeseen costs and unexpected time sinks involved, you’re right. Don’t feel too sorry for me, though: even after all of this, I still make money from selling Floppy Emus. But with all the labor involved, it’s basically like I’ve invented a new part-time job for myself. It pays more than minimum wage, but not by much. 🙂

Hardware

Enough of all this business stuff – let’s talk about what’s happening with the hardware! The good news is that Floppy Emu is working well in the wild, and I haven’t had any reports of major problems or incompatibility. The worst problem seems to be one I encountered myself: on my Mac 512K, maybe one in ten times the computer will fail to boot, and will show a Sad Mac error. I suspect this is because the drive speed emulation for the Mac 512K (and Mac 128K) is imperfect, and so the Mac sometimes freaks out when it thinks the floppy drive is rotating at the wrong speed. Newer Macs don’t use the drive speed signal and so don’t run into this problem. On the other hand, maybe it’s just something flakey about my 512K.

LCD

The LCD has been a source of headaches. About 10% of the LCD modules I’ve purchased have been defective in some way: damaged screens or dead pixels. That’s annoying, but the bigger headache has been varying contrast between LCD modules. Using the same software contrast setting, some modules show nice crisp text, some are washed out, and some are nearly solid black. I think it has something to do with how the LCD glass is mounted on the module, as I can usually change the contrast by pushing on the glass with my finger.

For the LCDs that don’t look good with the default contrast setting, I’ve been making custom firmware versions with a different contrast value, so every Floppy Emu that ships should have a nice display image. This isn’t a good long-term solution, though. It’s time consuming, and the customized firmware will be lost if the user ever applies a firmware update. People can make their own custom firmware, but it’s a hassle. What I probably need to do is add a manual contrast adjustment feature to the firmware, with the selected contrast value stored in EEPROM. Then everybody can tune the contrast exactly how they want it.

The revision 1.1 board that’s shipping now was designed to backlight the LCD, and the LCD modules have backlight LEDs built-in. After doing a few samples, though, I decided it looked better without backlighting. The backlight highlighted imperfections in the display glass, and gave it a washed-out look. All the Floppy Emus that are now shipping have the backlight disabled, but for people who really really want backlighting, they can add a 220 Ohm resistor at location R5 to enable it. A future board revision will have a through-hole footprint for R5 instead of a surface-mount footprint, to make it a little easier for modders.

Future Development

Time permitting, I hope to continue development of the Floppy Emu firmware. Some early adopters discovered that Floppy Emu works with the Apple IIgs, but it’s not as simple of a setup as I’d like. It works when the Floppy Emu is connected to the pass-through board of a real 3.5 inch Apple external drive, but not when Floppy Emu is connected directly to the IIgs. I’m pretty clueless when it comes to all things IIgs-related, so I’m not sure what’s going on, but I hope to find out.

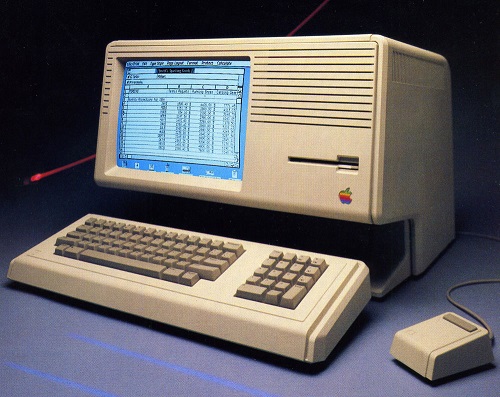

According to what I’ve read, it should also be possible to make Floppy Emu work on a Lisa – the precursor to the Macintosh. This would require a firmware change, since Lisa disks have essential data in the “tags” section of each sector, but the Macintosh doesn’t use tags and Floppy Emu ignores them. This may never happen, though, since the Lisa community is such a small audience of potentially interested people. I’m not ready to plunk down thousands of dollars for a Lisa just to test it out.

The most exciting thing on the horizon is HD20 support. The HD20 was a very early Apple hard drive from before the introduction of SCSI, and it connected to the external floppy port. In the past, several people have suggested HD20 emulation as a possible new feature, and I’ve always said it was impossible. But some new documentation that’s recently come to light suggests it may be possible after all – so Floppy Emu could emulate a 20 MB hard disk instead of an 800K floppy. In fact, it might even be possible to emulate hard disks larger than 20 MB. Unfortunately only a few early Macs have HD20 support in ROM, so it wouldn’t be a universal solution, but it would be great for those Macs that support it. It looks like HD20 emulation would involve a near total re-write of the Floppy Emu firmware, though, so don’t expect to see it next week!

Read 4 comments and join the conversation