Off To The Board House

The Tiny CPU board design is now off to the board house for manufacturing. The three week wait begins. Somewhere during that time, the Backcountry Logger boards should come back too.

The Tiny CPU board design is now off to the board house for manufacturing. The three week wait begins. Somewhere during that time, the Backcountry Logger boards should come back too.

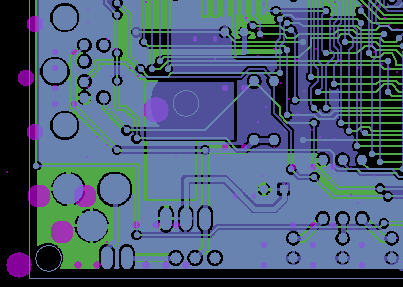

I selected Seeed Studio’s Fusion PCB service, because it was by far the cheapest prototype-oriented board house for a board this size (12.4 sqin) with multiple copies. I’m a little worried, though, because the Fusion PCB CAM file for Eagle appears to have a bug. I don’t know much about what the CAM file does, other than that Eagle uses it to generate the individual Gerber files from the Eagle .brd file, and all the board houses I’m aware of provide a CAM file you’re supposed to use. Using the Fusion PCB CAM file, and viewing the resulting Gerbers in gerbv, all the drill holes were offset about 250 mils below-left relative to the other layers. You can see this in the image above: the drill holes are shown in pink, and are clearly misaligned with the top and bottom copper layers in blue and green.

Processing the same .brd with the CAM files for BatchPCB and Dorkbot PDX did not have this problem. In the end, I used the BatchPCB CAM file, and sent the resulting Gerbers to Seeed along with a note explaining what happened. Hopefully it will be fine.

After I sent the board for manufacturing, I had a nasty surprise when I went to order the parts. The particular SRAM and ROM types and packages were selected because they were cheap “closeout” deals at Jameco, my friendly neighborhood electronics supplier. I guess they weren’t kidding about them being closeouts, though, because when I returned to the Jameco web site to make a purchase, a few days after having selected those chips, they were no longer listed for sale. Doh!

I was able to find the same SRAM (an ISSI 62LV256 in SO14 package) at Digikey, but the Flash ROM (AM29LV040B in PLCC package) wasn’t available there or anywhere. Fortunately eBay saved the day, and I was able to get two for a few dollars. Lesson learned: buy the parts before you manufacture the board. Or choose more commonly-available parts instead of legacy parts on closeout.

Read 1 comment and join the conversation1 Comment so far

Leave a reply. For customer support issues, please use the Customer Support link instead of writing comments.

Hi-

I had the same problem with Seeed’s CAM job in Eagle.

It turns out that either checking or un-checking (I can’t remember which) the “pos. Coord” box in the DrillsHoles tab in the CAM processor will fix this problem.

-Matthew