Circuit Sleuthing: Unidisk 5.25 Enable and PHI1

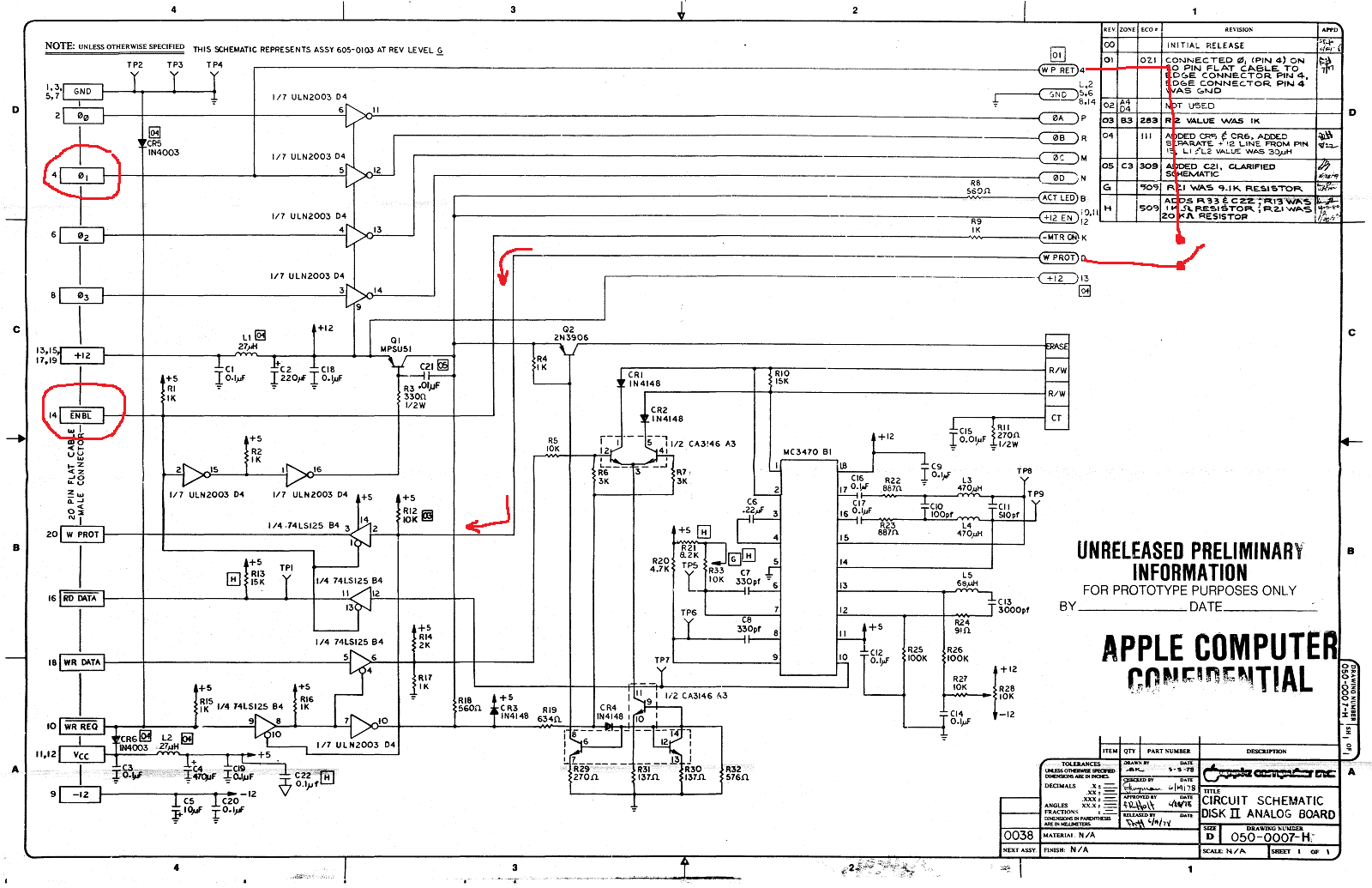

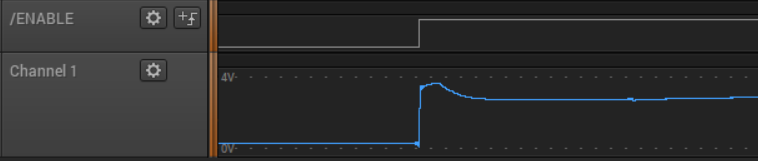

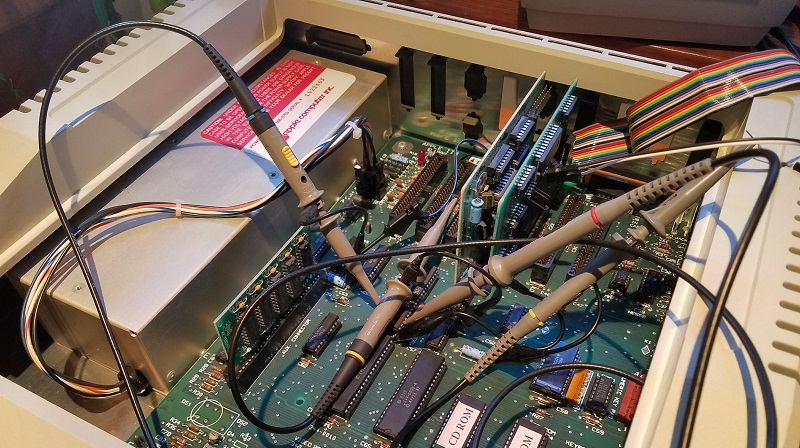

While chasing down some Yellowstone hardware bugs, I discovered an unexpected analog-type behavior on the enable input of the Unidisk 5.25 (A9M0104). This is an active low digital input that’s used to enable or disable the disk drive. Under the right conditions, something inside the drive itself is creating a substantial load on this input signal, or actively driving the signal. So instead of a nice clean 0 to 1 transition, I see stuff like the graph shown above. When the intended enable output from Yellowstone switches from low to high, the actual signal climbs from 0V to about 3.3V (on a 5V system) for about 50 microseconds, then quickly drops to 1.2V, then starts slowly rising. Then about 250 microseconds later when the PHI1 input switches from high to low, the enable signal crashes to 0V before quickly recovering to 2.9V, and eventually reaching 3.3V again. This causes buggy behavior and errors. Hmmm.

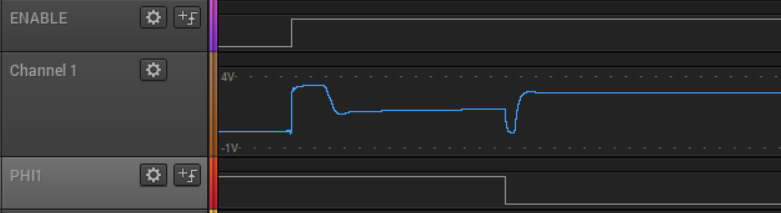

This problem only happens when PHI1 is high at the time when the enable signal is de-asserted. If PHI1 is low, the the enable signal follows a clean transition from 0 to 3.3V:

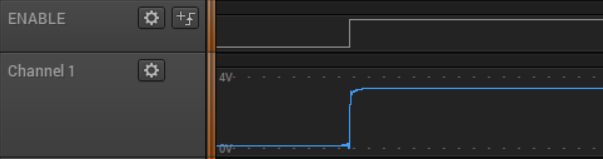

If PHI1 is high, but remains high forever instead of transitioning like the first example, then there’s still trouble with the enable signal, but the crash to 0V doesn’t happen:

The Unidisk 5.25 isn’t a very common drive, and many Apple II collectors have never heard of it. For comparison, here’s a repeat of the first example with a common Disk II drive instead of the Unidisk 5.25. There’s something strange, but it’s not as severe, and the crash to 0V doesn’t happen:

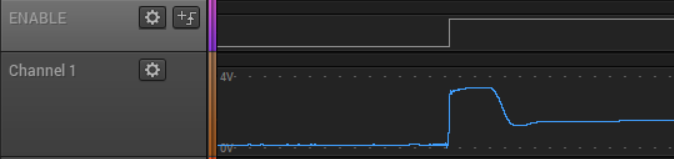

That’s all the evidence. Now let’s look at some schematics to try and determine what’s going on here.

Schematics Research

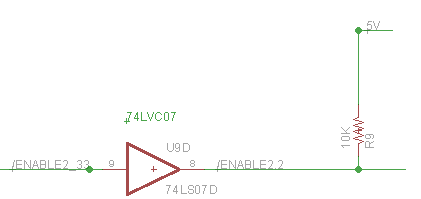

Yellowstone has two independent disk connectors. This weirdness with the enable signal only happens when the drive is connected to Yellowstone’s J2, which uses a different method than J1 to create the enable output. For J1, the enable signal is actively driven high or low by a 74LS244. But for J2, the enable signal is actively pulled low by a 74LVC07, and passively pulled high by a 10K pull-up resistor to +5V:

This creates a weak enable high signal for J2, which is certainly part of the problem here. But before saying “you shouldn’t do it that way”, I’d like to understand why this doesn’t work here, and what exactly is going wrong.

The first oddity is that even when the system’s at rest, the enable voltage is about 3.3V rather than the expected value around 5V. Since the high signal comes from the 10K pull-up resistor, the voltage should theoretically be about 5V as long as nothing in the drive is consuming more than a tiny amount of current from the enable signal. So it seems something in the drive *is* consuming appreciable current from the signal, or is otherwise influencing the signal voltage.

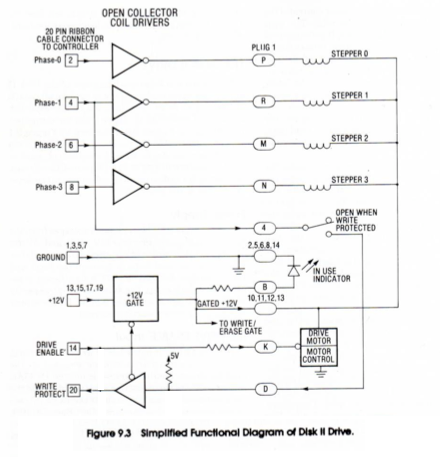

The second oddity is PHI1’s influence. What does PHI1 have to do with anything, and why should it affect the enable voltage? The PHI0 to PHI3 inputs are normally used to control the stepper motor for switching between tracks on the disk. But the PHI1 signal also has a second purpose related to the write-protect detection circuit:

You can confirm this by checking the schematic for the Disk II analog board, although the write-protect switch itself isn’t shown:

(click the image for a hi-res version) PHI1 is routed through the write-protect switch and becomes the value for the WPROT output, and is also used to gate the WRREQ input and prevent writing to write-protected disks. This explains why PHI1 is different from PHI0, PHI2, and PHI3, but not how it might affect the ENABLE input signal’s voltage.

That’s the Disk II. What about the Unidisk 5.25? It should be very similar, but unfortunately I can’t find any reliable schematic of the Unidisk 5.25 analog board. There’s this Unidisk 5.25 schematic, but I’m not sure it’s what it claims to be. It shows a drive with two 25-pin connectors, but the Unidisk 5.25 only has a single 19-pin connector. There’s also this Unidisk 5.25 PCB image, but it also shows two 25-pin connectors. I think both of these may actually be for the Duodisk, or for some never-released prototype, rather than for the A9M0104 Unidisk 5.25. So we’re forced to guess about what’s inside the Unidisk 5.25, with the knowledge that it’s mostly the same as the Disk II except with a half-height drive instead of full height.

A few things on the Disk II analog board schematic are noteworthy. The ENBL input has a 1K pull-up resistor to +5V (R1), so the 10K pull-up on Yellowstone isn’t relevant or necessary for this particular drive. ENBL is connected to three digital inputs. Two are 74LS inputs with input current about 0.1 mA, and the third is some type of inverter/transistor array with an input current around 1 mA. That’s a fairly large amount of input current. If my math is right, 1.2 mA though the 1K pull-up resistor R1 would drop 5V down to 3.8V, which is at least in the general neighborhood of the 3.3V that I measured.

ENBL is also connected through a 1K series resistor R9 to something called -MTRON. That’s not shown, probably because it’s part of the Shugart drive mechanism and not the analog board. What’s there? Given the series resistor and the fact that ENBL is active low, I’m guessing maybe there’s a PNP transistor at -MTRON? What else is there? Could this be the source of all the strangeness?

When the write-protect switch is closed, PHI1 will have an extra 10K pull-up to 5V at R12. It will also be connected to a couple of 74L125 inputs. But I don’t see any capacitors or other interesting details on the PHI1 circuit path that might explain what’s happening. Except for the power supplies, I don’t see any inductors or capacitors anywhere that look like they might cause the weird behavior I’ve observed.

Could the +5V supply inside the Unidisk 5.25 be changing? It’s isolated from the external +5V input by an inductor, so it’s possible. And resistor R1 would cause any large change on the internal +5V to influence the ENBL voltage too.

It’s worth mentioning that the Unidisk 5.25 is known to have something strange about its write-protect circuit behavior, and the drive isn’t compatible with the Apple IIgs ROM 03. But I’ve never found any definitive explanation for just what it is about the Unidisk 5.25 that’s different. I discussed this in another blog post from a few years ago, but in a different context, and my information about the Unidisk 5.25 was mostly speculation:

There’s also a Unidisk 5.25 analog board Twitter thread in which another Apple II hacker pondered some of the same questions about the write-protect circuit, but I don’t think he ever found answers.

According to some Yellowstone beta testers, the Disk IIc A2M4050 also has similar problems when it’s connected to Yellowstone’s J2. I don’t have a Disk IIc, so I can’t confirm if it’s the same enable voltage problem as the Unidisk 5.25, but I’d bet it is.

Solutions?

Without knowing exactly why the Unidisk 5.25 behaves this way at Yellowstone’s J2, I can still see a few potential solutions.

The easier solution is to make the enable signal’s pull-up stronger, so it more closely approximates an actively-driven signal’s logical high output. I was able to test this by paralleling an additional resistor with Yellowstone’s pull-up. I tried successively smaller and smaller pull-up resistor values (stronger pull-ups), and the enable signal gradually improved, and the “crash to 0V” became a crash to 0.5V, then 1.0V, etc. With 470 ohms in parallel with the original 10K ohms, the low point of the crash was improved to 2.0V and the drive began working normally. This solution acknowledges that something unexplained is pulling ENBL low, so it compensates by pulling ENBL high more strongly. But it doesn’t actually explain the problem, and it means about 12 mA would be wasted in Yellowstone’s 74LVC07 whenever J2’s enable is driven low.

The better solution is probably to redesign the Yellowstone PCB, so J2’s enable can be actively driven high and low, instead of using the ’07 and a pull-up resistor. Then J2’s enable circuit would match J1’s. I didn’t do this initially because I ran out of buffer pins, and didn’t want to add another chip just for this one signal. Even now, when I consider the prospect of revving the PCB yet again, and going through another round of verification and beta testing, I feel sick.

A possible third solution might be to leave the hardware as-is, and solve the problem in firmware. Since I’ve characterized the problem and when it happens, maybe I can tweak the firmware to avoid it. For example, maybe I can ensure PHI1 is always low before J2’s enable is de-asserted, or else insert a few milliseconds of blanking time whenever J2’s enable is de-asserted, to ensure nothing else happens while the enable signal voltage is acting strangely. But any firmware solution would be more like a bandage than a true fix, so it’s probably better to identify and fix the root cause.

Read 5 comments and join the conversationApple IIgs 80 Column Mode Crash

Here’s the part of our program where I describe a problem I’m having, and somebody tells me what I’ve done wrong, because I’m not smart enough to figure it out myself. The problem is with the Yellowstone disk controller, the Apple IIgs, and 80 column display mode. It’s a minor issue, but so far it’s defeated my attempts to fix it.

If you hold the Control-D keys during boot-up, Yellowstone will change its behavior and briefly display a text message “YELLOWSTONE DISK II MODE”, then continue booting. This works well on all the computers that the beta testers and I have tried, except for the Apple IIgs when the display type is set to 80 column mode. In this one case, the computer immediately crashes into the Apple II monitor when cold booting and holding Control-D.

- Holding Control-D during a reset works OK. It only crashes from a cold boot after you turn on the power switch.

- If the IIgs display type is set to 40 column mode, it works OK.

- If I replace the calls to HOME and COUT (the ROM’s text output subroutines) with NOP instructions, then it doesn’t crash anymore in 80 column mode, but I don’t get my text either.

I’m guessing there is 80 column firmware somewhere that’s not yet initialized during a cold boot, or that some Apple II soft switches for 80 column mode aren’t yet configured. That would explain why it works OK when I reset the computer with Control-OpenApple-Reset, and only fails from a cold boot. I vaguely recall reading somewhere that 80 column support is implemented as a virtual peripheral card in slot 3, which won’t have been initialized yet when my card in slot 6 is being initialized, because higher numbered slots are initialized first.

According to the docs, the soft switch at address $C00C will turn off 80 column mode. I tried making the Yellowstone firmware touch this address before calling HOME and COUT, but it still crashes. I also noticed that touching $C00C interactively from the Apple II monitor prompt will turn off 80-column mode but also locks up the computer with a weird animating pattern, so I’m not sure that’s the correct method of disabling 80-column mode. These Apple II soft switches can sure be challenging to understand.

Read 6 comments and join the conversationGlobal Chip Shortage Hits Home

Discouraging news from the BMOW manufacturing front: the global chip shortage seems to be growing worse, and is now causing major problems for some of my vintage computer products. This is a change from a year or two ago, when the shortage mostly affected new high-end semiconductors that BMOW doesn’t use anyway. Since then I’d noticed that prices were rising on lower-end semiconductors, with some parts shortages, but I was mostly able to absorb the costs or find alternative parts. In the past three to six months, the landscape has changed. Many of my essential parts have become difficult or impossible to find. This jeopardizes the continued viability of several BMOW products, including Yellowstone and the Floppy Emu.

When searching for semiconductor parts using a specialized search engine like Octopart, at first it may look like the major suppliers are sold out but secondary suppliers still have stock at reasonable prices. Unfortunately I’ve learned not to trust this, and some of the secondary suppliers seem to be intentionally deceptive. They list parts they don’t have, at prices they’re not actually willing to accept.

Twice in the past week, I’ve placed an order with a secondary supplier for thousands of dollars in hard-to-find chips. The order is made and confirmed and paid. My credit card is charged $4000. Feeling good that I’ve sourced the hard-to-find part, I go ahead and buy all the other parts needed to begin manufacturing. And then three days later I get an email from the supplier saying “those parts are already sold, sorry”. Or worse, “the price on those parts you already bought for $5.17 is retroactively increasing to $20.97.” I try not to take it personally, but I can tell you I really blew up over that second one.

Yellowstone’s First Manufacturing Run May Be Its Last

I’ve been working on the design of the Yellowstone universal disk controller for Apple II for more than four years. I’m finally almost to the point of starting manufacturing. At the time I started the design, the Lattice MachXO2-1200 FPGA was a widely-available part for about $5. Now it’s basically impossible to find. A few of the questionable secondary suppliers may have some, for a much higher price, or their listings may be fiction. I could substitute the next higher member of the same FPGA family, the MachXO2-2000, but that’s also unavailable.

Will MachXO2-1200 availability improve any time soon? I’m not counting on it. I have about 250 of them that I bought last summer, so in theory I can manufacture at least that many Yellowstone cards, if I can also find the other necessary components. Even very common parts like a 74LVC244 bus driver are becoming difficult to find, so that’s not guaranteed. Unfortunately this means Yellowstone’s first manufacturing run may also be its last manufacturing run, at least for a while.

The Future of the Floppy Emu

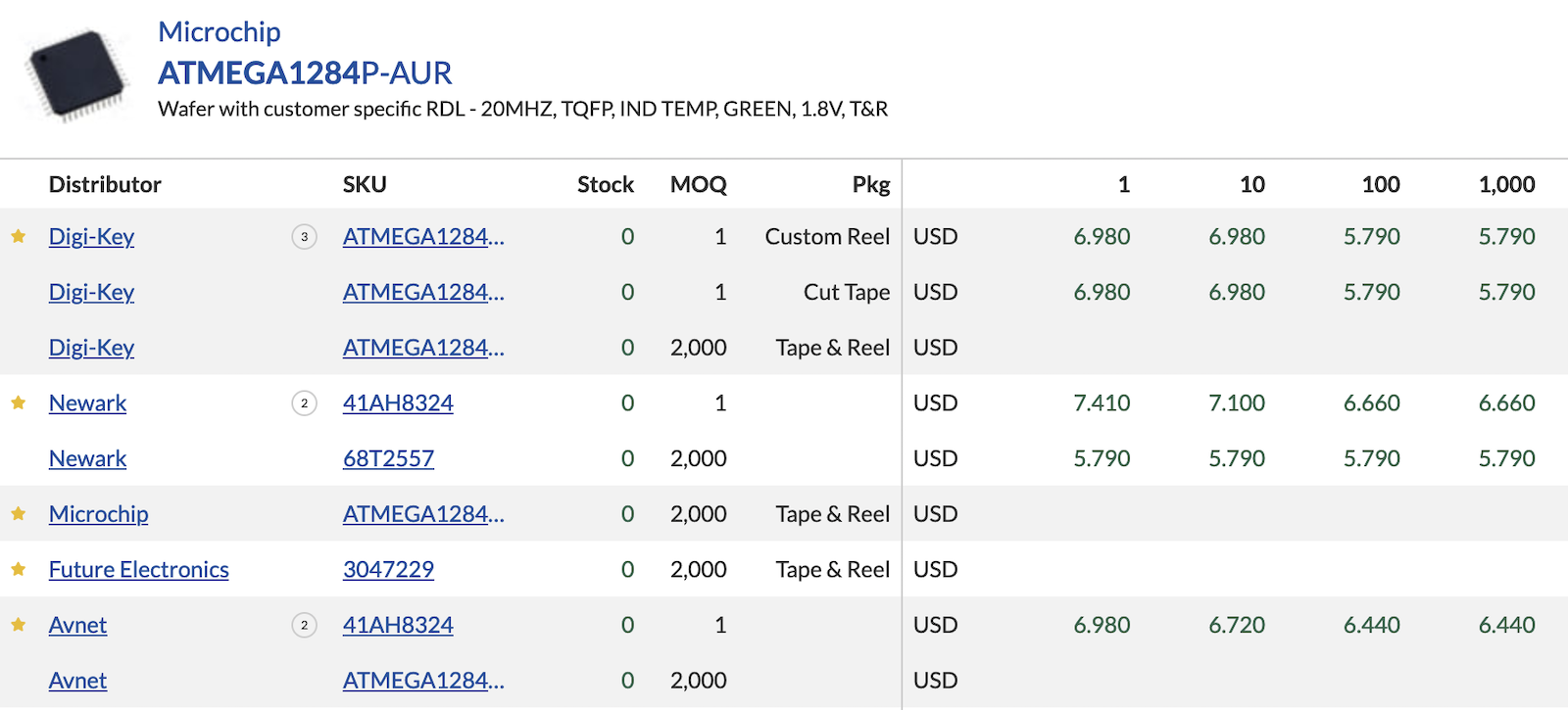

The inability to build Yellowstone cards would be very unfortunate, but the inability to build Floppy Emu boards would be disastrous from a business standpoint. But I fear this may be where things are headed. The two primary chips used in the Floppy Emu are the ATMEGA1284 microcontroller and the XC9572XL CPLD, and both of them now have limited or no supply. I’m currently in the midst of starting a new production run of Floppy Emu boards, and it’s been very tough to source all the parts. I was eventually successful (assuming suppliers don’t retroactively cancel or modify my paid orders for a third time), but in six months when I go to do this again, there’s a good chance the parts simply won’t be available anywhere at any price.

Forcing a Redesign

Faced with zero availability of a key part, the only real solution is to redesign the product to use a different part. That costs lots of time and money, could introduce new bugs, and is definitely not something I’m eager to do. But if the alternative is retiring the product, do I really have a choice? There could be some upside too, as different parts or newer parts might eventually help support new product features.

If I’m going to redesign an existing product around new parts, it’s absolutely critical that the new parts are free from supply risk themselves. I can’t spend months redesigning a product, only to have the new parts become unavailable just like the old ones did. So if I’m choosing a new part now, I want to see that it’s available from several different authorized suppliers, and that the suppliers have thousands of them currently in stock. That will tell me it’s a popular high-volume part, not some niche part that may have its own supply problems in six months.

Looking for alternatives to the XC9572XL, I searched for other programmable logic parts with a similar amount of logic space (72 macrocells here). I eliminated all the parts in BGA packages, because I’m just not prepared to tackle BGA prototyping or assembly – I need chips with actual exposed pins. Then I eliminated all the parts that don’t have widespread availability and thousands of stock. That didn’t leave many options remaining. The leading choices are probably the XC9536XL, which is the same part I use now except with half the logic space, or else some low-end members of the same MachXO2 FPGA family that I’m using for Yellowstone.

Microcontrollers – The New Unobtanium

Next I turned my attention to finding an alternate microcontroller, and this is where my heart really sank. I searched for microcontroller options with:

- at least 40 I/O pins

- at least 16K RAM

- exposed pins

- a mainstream architecture like ARM or AVR

- stock level in the thousands

The result of my search was basically nothing. I was floored.

What happened to all the Atmel microcontrollers? The STM32 stuff? Texas Instruments? Microchip? Anybody? Hello?

I tried going directly to the ST Microelectronics store, and viewed their STM32 Mainstream MCU section. There are 1152 different microcontrollers in this section, of which only 16 are in stock! How is that possible? Has their entire factory shut down?

OK, you’re right, it’s a lie to say there are no microcontrollers that satisfy my search. DigiKey shows 932 results when I ignore the stock level. But if I’m going to bet the farm on a new MCU, I want to see a stock level in the thousands, and that limits the choices to just a few dozen, virtually all of which aren’t what I’d consider “mainstream”. It’s 2021, am I really going to redesign my whole product around a dsPIC or some weird thing from Renesas? Does anybody actually use the AVR32 stuff for real products? The ARM Cortex parts dominate the microcontroller space these days, and they’re available from several different manufacturers. If I’m starting a new design, that’s probably the most sensible choice to ensure long-term availability. So let’s make that a requirement.

Despite their huge popularity, ARM Cortex MCUs matching my requirements just aren’t available in large quantities from anyone right now. What are other businesses using for their new microcontroller-based product designs? I don’t know.

If I eliminate microcontrollers from obscure vendors I’ve never heard of, the only parts I can find that might possibly work and are widely available are:

- Atmel SAM3 and SAM4 families

- Texas Instruments Tiva C family

That’s the whole list. I don’t really know anything about the Tiva C or the Texas Instruments dev tools, so that leaves the Atmel SAM stuff as the only choice. The available options aren’t the most desirable ones, though. If I were choosing an ATSAM part, I’d probably choose a Cortex-M0, or something like the popular ATSAMD21 or ATSAMD51. But the available options are in the less popular members of the SAM family like the SAM4L and SAM3S. So… yeah. I’m not sure what to do. I’m afraid we’re headed for a difficult time ahead. Here’s hoping the global chip shortage starts to ease soon.

Read 24 comments and join the conversationYellowstone Beta Testing Continues

The goal of a “do everything” disk controller for Apple II is getting closer to reality, thanks to the efforts of the hard-working beta testers. If all goes well, I’m hoping to have Yellowstone cards available for sale in the first months of the new year. Yellowstone is designed to support virtually every type of Apple 5.25 inch, 3.5 inch, or smart disk drive that exists, including Macintosh drives running on the Apple II, and the results from the beta testers have been very encouraging so far. But it’s not all perfect. Here are a few of the issues that beta testing has uncovered.

Unidisk 5.25 and Disk IIc Problems at Drive 2

The Unidisk 5.25 and the Disk IIc work fine when connected as Drive 1, but in some situations they appear to interfere with Drive 1 if they’re connected as Drive 2. I don’t have the hardware needed to troubleshoot this one directly, but I should be receiving a Unidisk 5.25 next week. My best guess is that the outputs on these drives have a different type of driver circuit than other drives, which causes the tri-state signals to take longer than normal to get pulled to a logical “1” voltage by Yellowstone’s pull-up resistors. So their “0” outputs effectively overlap with Drive 1’s. Or it may be something completely different.

Third-Party 3.5 Inch Drive Problems

All of the Apple-brand 3.5 inch drives are working, including the Apple 3.5, Unidisk 3.5, Apple SuperDrive, and various Macintosh 3.5 inch drives. But third-party drives from Applied Engineering, Dataspace, Ehman, and Laser only work sporadically or don’t work at all. The Applied Engineering 3.5 drive is supposed to work with a stock Apple IIgs, but the other three reportedly don’t work with any stock Apple computer or disk controller, but do work with the original UDC disk controller. (It seems like that would have greatly limited their sales appeal.) I have a Laser 3.5 for testing, and I should be receiving an Applied Engineering 3.5 drive next week.

Obscure Crash on Apple IIgs

If your IIgs is configured for 80 column mode, and you use one of the several methods to enable Yellowstone’s Disk II mode immediately from power-on, it will crash. This doesn’t happen after a warm start or reboot, only directly from power-on. It also doesn’t happen in 40 column mode. I suspect my code that prints “YELLOWSTONE DISK II MODE” is doing something bad in 80 column mode. It just calls the HOME and COUT routines in the Apple II ROM. I haven’t looked into this further yet.

3.5 Inch Disk I/O Speed

Depending on what software you’re running and what you’re doing with it, 3.5 inch disk I/O through Yellowstone is anywhere from a little to a lot slower than 3.5 inch disk I/O with the same drive on the Apple IIgs built-in disk port. 5.25 inch disk I/O and smart disk I/O (like the Unidisk 3.5 and Floppy Emu Smartport Hard Disk) are about the same speed as the Apple IIgs built-in disk port. I’m not sure why 3.5 inch I/O is behaving differently, but it may be some combination of sector interleave and code optimization.

Possible Disk Corruption with VidHD

One tester reported that a specific Apple IIgs hardware configuration including VidHD would corrupt 3.5 inch disks during power-up. When VidHD was removed, the problem disappeared. I think this is actually a VidHD problem and not Yellowstone. There was a long discussion on Facebook’s Apple II group earlier this year about people experiencing disk corruption when using VidHD. Initial reports were that the latest firmware fixed it, but that was later called into question.

Possible Problems with TransWarp Accelerator

One tester reported problems when running Yellowstone on a specific unenhanced Apple IIe system with a TransWarp accelerator. The problem didn’t appear with the TW on a different computer, and couldn’t be confirmed by the only other tester with a TransWarp. For now it’s unclear if this is a Yellowstone problem or something else.

Cable Routing Difficulties

A few testers reported that the disk ribbon cables were difficult to route through the opening in the rear of the computer, or that the cables pushed against the card in the neighboring slot. I’ve experimented a bit with using right-angle connectors and some other ideas, but there’s probably nothing much I can do without changing the entire board layout. I think the testers experienced this frustration more often than a typical user will, because the testers are constantly plugging and unplugging different drives in order to verify them.

There are a few more open issues beyond these, but most of them are hopefully at the level of errata, and don’t need to delay production of the final Yellowstone cards. Any Yellowstone firmware bugs that are discovered after launch can be fixed with a firmware update, which can be done in-system on the Apple II computer without any special programming tools.

Be the first to comment!Cyber Monday 10% Off at the New BMOW Store

Help celebrate the opening of the new BMOW store with a Cyber Monday 10% off sale! You get a discount, I get more people trying the new store platform, and everybody wins. From now until the end of Monday, all BMOW products in the new store will be 10% off the regular price. This sale ends at 11:59 PM Pacific time (UTC-8) on Monday night.

You can visit the new BMOW store at shop.bigmessowires.com, and enter the discount code cyberbmow21 at checkout to get 10% off. This isn’t yet the default store, and most internal and external links still point to the original store at www.bigmessowires.com/shop. Purchases from the original store aren’t eligible for this sale – I need as many people as possible to exercise the new store to confirm it’s running smoothly, before I can deactivate the original store. Thank you for trying out the new store, and happy shopping!

Read 2 comments and join the conversationBMOW Store Gets a Major Remodeling

Just in time for the holiday shopping season, the BMOW store has been completely rebuilt using an entirely new technology platform! This brings an armload of major improvements, including new payment and shipping options, the restoration of Australia and New Zealand shipping, and overall much improved features and stability. This is something that’s been on my to-do list for years, but I kept putting it off, as there was always something more urgent. My procrastination continued until the old store mysteriously imploded on the night before Thanksgiving, leaving BMOW unable to process any new orders. Ouch.

The Store Died, Sorry

Some time on November 23rd or 24th, the old store’s payment processing quietly stopped working. There were no errors or other problem indications, except a mysterious lack of new orders and a large number of abandoned shopping carts. I didn’t notice anything was wrong until late night just before Thanksgiving as I was making pie. I found that customers could begin the checkout process, enter their payment details, and see the final order review page. But when they clicked the button to submit their order, it redirected them to a blank page. No visible error, nothing in the logs, but no payment was made, no order was submitted.

Unfortunately there was no one I could ask for help; I needed to solve the problem myself. I’ve done it before when something unexpectedly broke, sifting through logs, updating plugins, patching PHP files, changing security settings, or increasing server memory limits and timeouts. The old BMOW store is an awkward collection of cheap and free components, including a generic web hosting plan (Dreamhost), content management software (WordPress), e-commerce software (Woocommerce), a variety of different WordPress and Woocommerce plugins, and a payment gateway plugin (PayPal Express Checkout, from the PayPal for Woocommerce plugin). This system frequently breaks at unexpected times, when one of these components gets automatically updated, or a database table grows too large, or an external dependency changes. But I’m responsible for keeping it all working, and that’s not really a job I want to have.

I sunk many hours into troubleshooting this problem unsuccessfully. The logs didn’t reveal any errors or obvious failures. Dreamhost couldn’t help, beyond suggesting that I update everything to the latest versions. This is a double-edged sword in the land of WordPress, because updates are often needed to fix security issues or other problems, but they’re also the most common source of problems. When you’re relying on a dozen different components, and you update one of them, the others might not be happy.

After a frantic late night, I finally managed to fix the problem temporarily on Thanksgiving morning, by eliminating the order review step entirely. But it was now glaringly clear how much risk I was facing by depending on this fragile technology stack with nobody to maintain it but me.

Problems With The Old Store

Even if the old store had continued working OK, it just wasn’t great for customers or for me and Lea. On the customer side, it was very slow and sluggish. Submitting an order would sometimes lead to a 500 internal server error, or a payment made but no order recorded, or two orders for a single payment. Something about shipping options didn’t work correctly, so I was forced to limit customers to a single shipping method instead of offering a choice. The order confirmation and shipping confirmation emails sometimes didn’t work.

And then there was PayPal. The old store only offered a single payment processor, PayPal, which some customers simply hate and refuse to use. PayPal used to offer an option for credit card payments without creating a PayPal account if you didn’t want to, but that seems to have disappeared and now a PayPal account is required for making any kind of payment. Another drawback was the lack of payment integration – customers needed to leave the BMOW site in order to enter payment info at the PayPal site, before returning to the BMOW site for final order review.

PayPal also made it strangely difficult to edit the shipping address. If the customer already had a PayPal account, it would auto-populate the shipping address with their saved address, with no option to change it except by cancelling the order in progress and visiting PayPal preferences. Moved recently, or shipping to an alternate address? Too bad. PayPal’s address validation was also weirdly broken. I’ve had countless orders where people omitted required parts of their shipping address like the building number, city name, or state/territory name.

On the back end, searching for and updating customers’ order records was slow and awkward. Some apparently basic features were not included, like embedded the tracking number into the shipment confirmation email. I had to implement that myself with some custom coding. And while this may not be a fair criticism, the old store simply took orders but offered nothing towards managing shipping. I used a separate third-party shipping solution (Shippo), with a custom-made C# tool to gather the Woocommerce data, process it as needed, generate packing slips and invoices, and purchase and print the postage labels from Shippo.

Hello Shopify!

Shopify is a very popular solution for running e-commerce stores, and I’d already made up my mind long ago to try Shopify when I was ready to update the store. Shopify replaces the entire technology stack of the old store: Dreamhost, WordPress, Woocommerce, plugins, PayPal, and Shippo. It’s a cloud-based solution, so Shopify actually runs your store on their servers, using DNS magic to make it appear under your domain name as part of your regular web site.

Unfortunately Shopify isn’t exactly cheap, at $79/month for the plan I would probably need. But after all the pains experienced with the old store, I decided the money was well worth it. And now that I’ve dug into Shopify’s details further, I think the net cost may be much less than $79/month, thanks to lower fees for credit card processing and shipping than I was paying before. In fact, I may actually see a net savings from switching. Wow!

I was able to create and configure the new Shopify store in one very long day. So far I’m extremely pleased and impressed with what I’ve seen. Everywhere I look, from the theme designs to the order processing and back-end reporting, I find great new features that are a huge step up from what the old store provided. I should have made this switch long ago.

What’s New

The new store looks completely different from the old one, but the customer-facing changes are more than just a facelift. Here’s a tour of what’s new:

New Payment Options – The store uses Shopify Payments, which seems to be a rebranded Stripe. It allows for a dozen different payment methods, including credit cards and others like Apple Pay. It’s all directly integrated into the store, with no separate account needed. Basically it just works. GOODBYE PAYPAL! I will not miss you at all. But PayPal is still an option for anyone who wants it.

New USA Shipping Methods – For customers in the USA, instead of one-size-fits-all shipping, you now have a choice of Standard (3-4 day) or Economy (5-8) day shipping. For the moment these correspond to USPS Priority and USPS First Class Mail, but that may change in the future. If you want to save a few bucks on shipping and are willing to wait slightly longer, now you have that choice.

Free USA Shipping – Orders over $150 to destinations in the USA will now ship free. Hooray!

New International Shipping Methods – Worldwide DHL and UPS shipping is here! This is a big change, and I’m excited and slightly nervous. These new shipping methods aren’t cheap, at around $50 for most destination countries, but they should be faster and much more reliable. Higher tiers of USPS international service are now available too, including Priority Mail International and Priority Mail Express International. USPS First Class Package International Service remains an option too, and is the lowest cost international shipping method. FCPIS is sometimes great, and you can typically get a package delivered in a week to destinations like Canada, France, or UK. But sometimes FCPIS experiences wild delays with months passing in shipping purgatory without any updates to the tracking info. This is very frustrating for both customers and for me.

I hesitate to call any of these new international shipping methods “express shipping”, because there’s still a few days of order processing time before BMOW can fulfill your order, no matter how fast the actual shipping may be. Our fabulous office specialist Lea normally works three days per week, so the processing time is 1-2 business days in most situations.

The shipping fee for international orders is also now calculated based on the actual carrier cost, plus a small handling fee for the extra work that these orders involve. This is an improvement over the old pseudo-flat-rate pricing scheme for international shipping, which lumped everything into a few broad categories based on weight tiers and geographic region.

Australia and New Zealand Shipping – US postal service FCPIS shipments to Australia and New Zealand have been suspended for the past two months, due to some unspecified “carrier disruptions” related to COVID-19 and global supply chain problems. The introduction of new shipping methods means that BMOW can once again serve customers in those countries. Woo-hoo! Australia Post’s ShopMate USA service also remains an option for customers looking for the cheapest Australian shipping, although the service will reportedly be phased out next year. We hope that FCPIS service to these countries will become available again soon, but until then, these are good alternatives.

Better Tracking – Improved package tracking and notifications are one of the many other improvements made possible by the new store. For international shipments, DHL and UPS will provide much more timely and detailed tracking information than FCPIS. And for customers everywhere, you’ll get email notifications not just when your package is shipped, but also when it’s out for delivery. There’s even an option to get notifications on your phone by text message.

Tour The New Store Today!

The new BMOW store is live and taking orders now at shop.bigmessowires.com. Give it a try! For the moment, both the old store and new store are running and accepting orders, so I can monitor what’s happening at the new store and ensure everything goes smoothly. All the store links are still pointing to the old store, so you’ll need to enter the URL directly (or click the link in this paragraph) to visit the new store. Eventually I’ll retire the old store and set up redirection links for each of the product pages to the new store. If you try the new store, please let me know how the experience goes. What are your thoughts on the visual design and page layout? Any issues with order processing or payments? Thanks for your feedback!

Read 6 comments and join the conversation